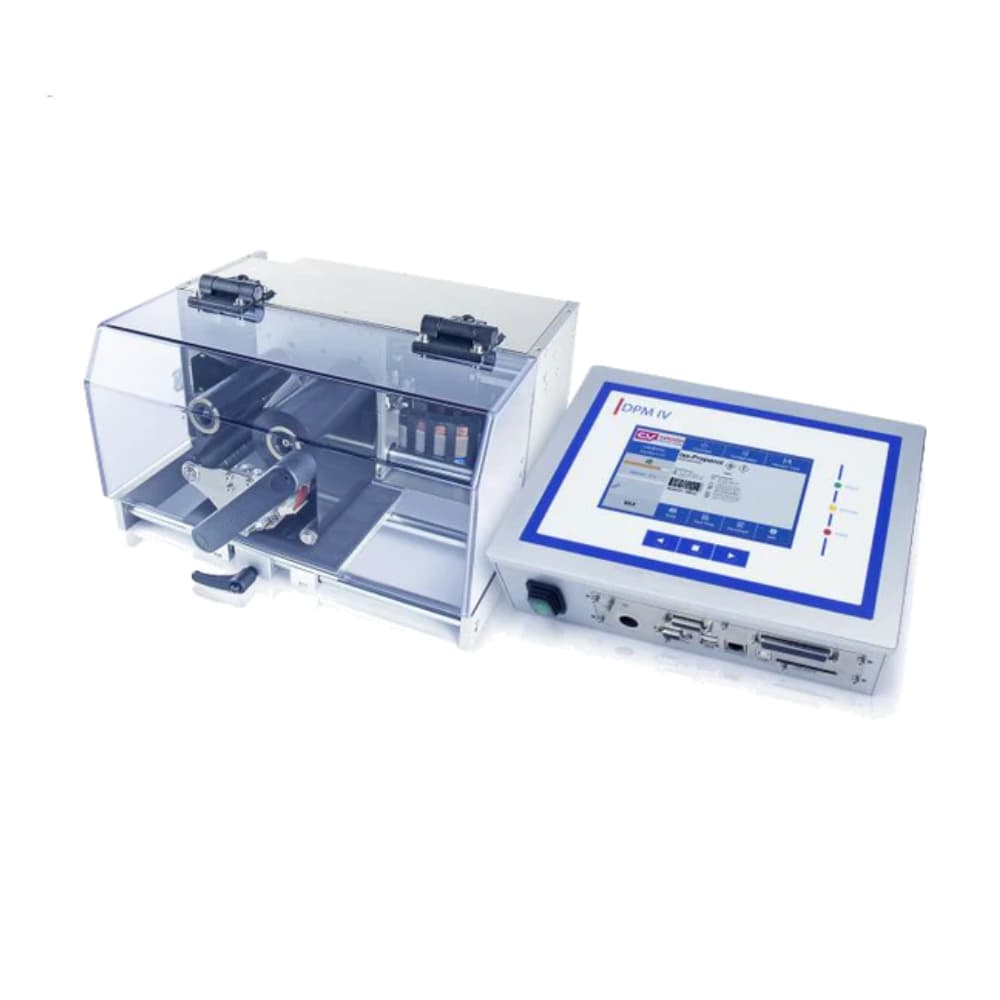

Un TTO est un appareil d'impression numérique qui transfère l'encre d'un ruban chauffé sur un emballage souple pour imprimer des informations variables telles que des dates, des codes de lot, des codes-barres et des graphiques.

Les imprimantes à transfert thermique (TTO) permettent une impression nette et durable de codes-barres, de textes et d'images directement sur des films d'emballage souples. Idéales pour le codage haute résolution sur étiquettes et emballages, ces imprimantes offrent une qualité d'impression rapide, nette et fiable, avec une maintenance minimale pour une production continue.

Produits

Imprimantes à transfert thermique (TTO) – Solutions de codage et de marquage industriels haute résolution

Modernisez votre ligne de conditionnement avec des imprimantes à transfert thermique (TTO) haute performance, conçues pour une impression de données variables nette, durable et à grande vitesse. Que vous imprimiez des codes-barres, des dates de péremption, des listes d'ingrédients, des étiquettes nutritionnelles, des numéros de lot ou des données sérialisées, nos imprimantes à transfert thermique industrielles répondent à tous vos besoins. Les surimprimantes offrent la précision et la disponibilité dont vos opérations ont besoin.

Chez Redemac, nous proposons une gamme sélectionnée de produits de transfert thermique conçus pour une production continue, une maintenance réduite et une qualité d'impression exceptionnelle sur des matériaux d'emballage souples.

Pourquoi choisir le surimpression par transfert thermique (TTO) ?

Contrairement aux imprimantes à encre traditionnelles, la technologie TTO utilise une tête d'impression numérique de haute précision qui dépose l'encre d'un ruban directement sur l'emballage souple. On obtient ainsi des codes durables et à contraste élevé, adaptés aux lignes de production à grande vitesse des industries agroalimentaire, pharmaceutique et industrielle.

Principaux avantages de l'impression TTO :

- Impressions ultra-nettes et d'une précision pixel parfaite (texte, graphiques, codes-barres, codes QR).

- Qualité constante à des vitesses de défilement élevées pour les films défilant horizontalement ou verticalement.

- Faibles coûts d'exploitation grâce à une utilisation efficace du ruban.

- Une technologie propre, à base de rubans, sans fluides, sans solvants et sans salissures.

- Idéal pour les supports souples : films d'emballage, sachets, films et étiquettes.

- Extrêmement fiable pour un fonctionnement 24h/24 et 7j/7 avec un temps d'arrêt minimal.

Performances de qualité industrielle pour les environnements d'emballage exigeants

Notre collection d'imprimantes à transfert thermique industrielles est spécialement conçue pour :

- Emballages alimentaires et de boissons

- Boulangerie, confiserie et snacks

- Produits pharmaceutiques et nutraceutiques

- Cosmétiques et soins personnels

- Aliments surgelés

- Biens industriels et de consommation

- Produits ménagers

- Emballage de matériel et d'électronique

Que vous ayez besoin d'un mode intermittent, d'un mode continu ou de systèmes TTO tout-en-un, nous avons une solution adaptée à votre vitesse de ligne, à votre format d'emballage et à votre résolution d'impression.

Caractéristiques principales de nos imprimantes à transfert thermique

- Impression haute résolution jusqu'à 300 dpi

- Grandes zones d'impression pour les listes d'ingrédients, les logos, les avertissements relatifs aux allergènes

- Optimisation intelligente des rubans pour réduire les déchets

- Têtes d'impression de qualité industrielle conçues pour un fonctionnement continu

- Changements de ruban rapides et maintenance sans outil

- Micrologiciel intelligent pour l'impression de données variables

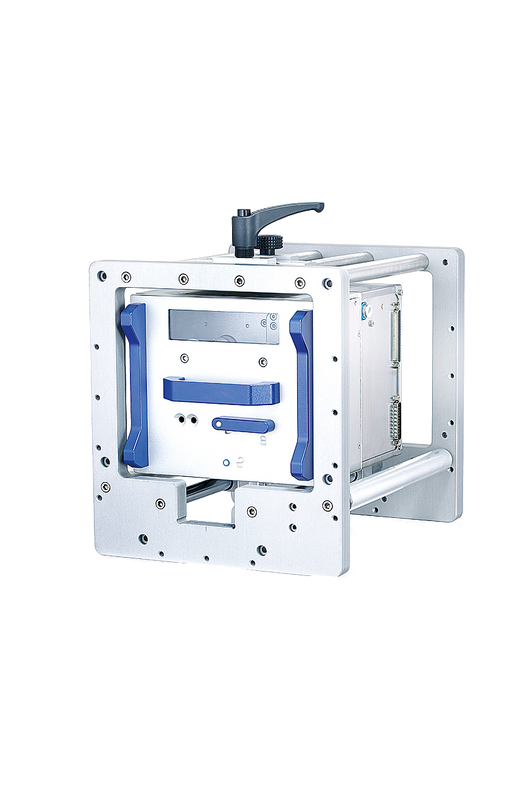

- Intégration transparente avec les machines de formage-remplissage-scellage verticales/horizontales (VFFS et HFFS)

- La technologie de codage propre et à sec est idéale pour les produits sensibles.

Choisir la bonne imprimante TTO : les points à prendre en compte

- Format d'emballage : flow-pack, sachets, pochettes, films ou étiquettes

- Mode d'impression : continu ou intermittent

- Zone d'impression requise : petits codes de date ou blocs d'ingrédients complets

- Vitesse de ligne : Exigences de qualité d’impression à haut débit

- Type de ruban : cire, résine ou mélange cire-résine, selon le support

- Conditions environnementales : humidité, température, poussière, lavages

- Exigences réglementaires : codage de sécurité alimentaire, traçabilité pharmaceutique

Pourquoi acheter votre imprimante TTO chez Redemac ?

- Conseils d'experts pour choisir le bon modèle TTO

- Accès aux marques leaders du secteur

- Assistance professionnelle à l'intégration des lignes de conditionnement

- Livraison rapide partout au Canada et aux États-Unis

- Prix compétitifs sur le matériel et les consommables

- Assistance technique fiable après l'achat

Bénéficiez d'une disponibilité accrue, d'une qualité d'impression supérieure et d'un codage fiable grâce à la gamme TTO de Redemac.

Découvrez les produits de transfert thermique de Redemac

Parcourez notre collection TTO pour trouver :

- Surimprimeurs à transfert thermique haute vitesse

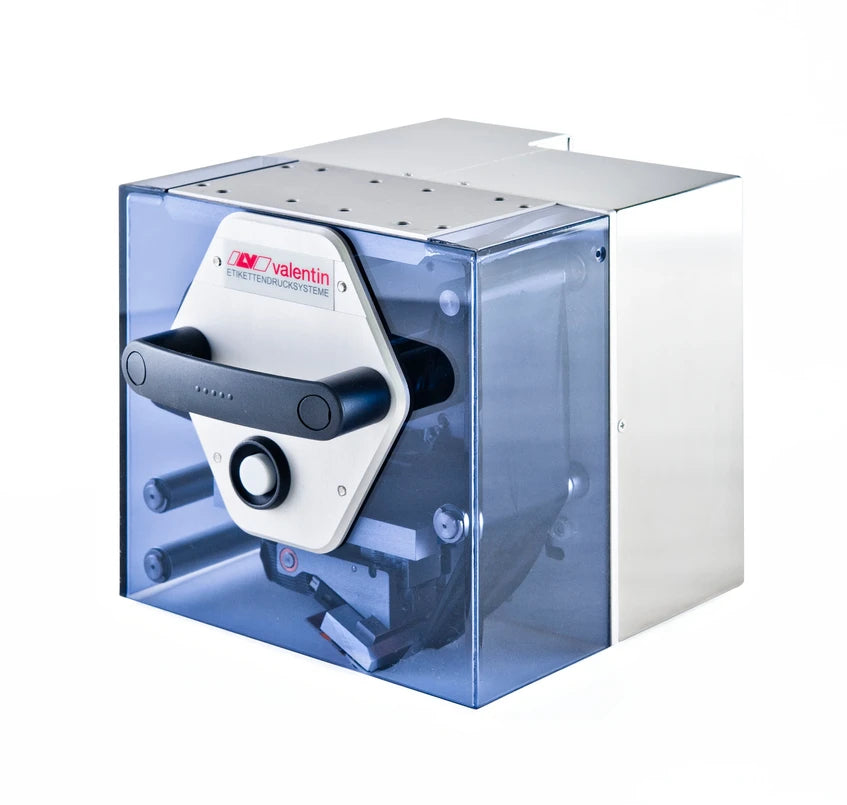

- Modèles compacts pour installations à faible encombrement

- Imprimantes grand format pour des zones d'impression étendues

- Accessoires, rubans et consommables

- Kits d'intégration pour machines d'emballage

Chaque produit de cette catégorie est sélectionné pour sa fiabilité, sa durabilité et son faible coût d'exploitation.

Questions fréquemment posées

Les imprimantes à jet d'encre continu (CIJ) utilisent de l'encre liquide et fonctionnent bien sur les surfaces rigides.

Les imprimantes TTO utilisent des rubans à transfert thermique et sont idéales pour les films d'emballage souples nécessitant des impressions nettes et haute résolution.

Films souples, sachets, feuilles d'aluminium, matériaux laminés, étiquettes et emballages flow-pack.

Oui, les impressions TTO sont résistantes aux taches, durables et très lisibles même après transport, congélation ou manipulation.

Cela dépend de la couverture d'impression, de la largeur du ruban et du mode d'impression ; les systèmes avancés optimisent l'utilisation du ruban pour réduire les coûts.