ALTECH

ALritma

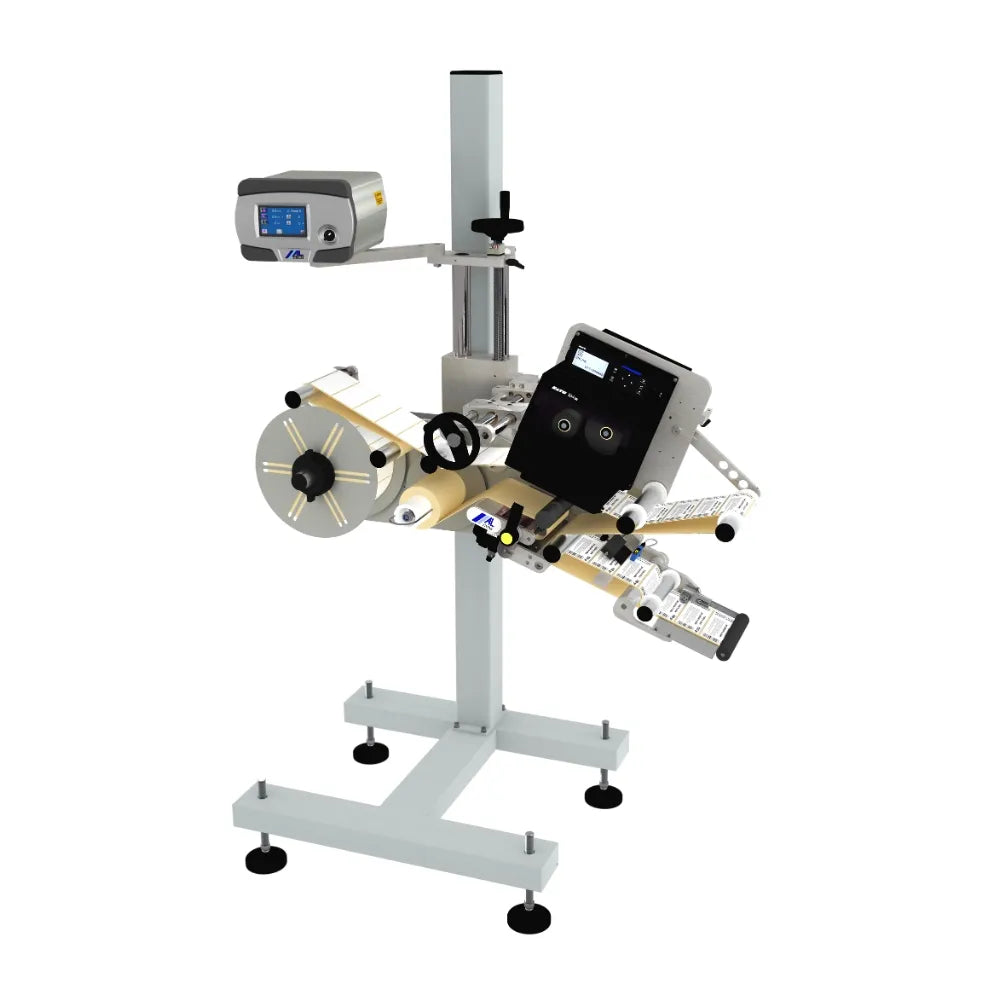

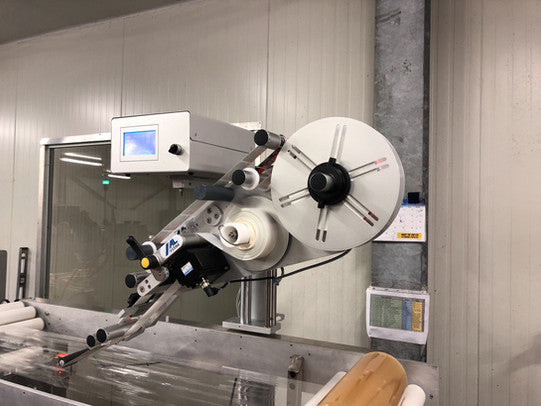

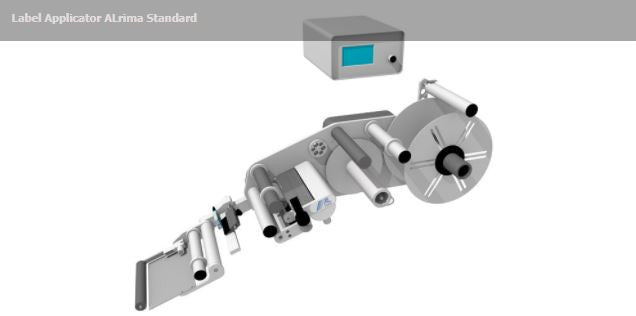

ALritma - High-performance label applicator

ALmatic can apply labels up to 200 mm in width onto bottles, vials and pots, flat or elliptical (ALmatic E), or cylindrical products (ALmatic C) of variable diameter from a minimum of 12 mm to a maximum of 110 mm.

There are three versions available: S, M, and L, for label widths up to 100, 200 and 300 mm, respectively.

Controls

The label applicator is controlled by a powerful microprocessor with a touchscreen display. The most frequently used parameters are displayed via intuitive icons which represent the various functions and provide advanced management, relieving the operator of the need to perform complex mechanical adjustments and noticeably speeding up format changes.

Available Functions

- Pre-dispensing adjustment in tenths of a mm

- Speed adjustment in 0.1 m/min increments

- Labelling delay adjustment in mm

- Acceleration/deceleration ramp adjustment

- Storage of different label formats

- Automatic recovery of missing labels

- Progressive and countdown piece counter

- Automatic removal of double product detection

- Shift register between product sensor and label application point

- End-of-roll alarm and web break alarm

- Output for connection to other systems

Optional Accessories

In addition to its sophisticated standard components, ALritma can also be equipped with a series of devices to increase its running time and performance:

- Additional unwind unit

- Increased diameter unwind unit (400 mm)

- Hot marker

- Sensor for transparent labels

- Pneumatic and air-blow applicators

- Near end-of-roll monitoring

- Correct label application monitoring device

- Non-stop monitoring device for two applicators installed in sequence

- Automatic speed control via encoder

- Serial interface for connection to Personal Computer.