A CIJ printer pumps ink through a nozzle continuously and breaks it into droplets; selected droplets are charged and deflected onto the substrate, while unused droplets are recirculated.

Continuous inkjet (CIJ) printers are widely used in industrial applications for high-speed, non-contact printing on a variety of surfaces. They work by continuously ejecting a stream of ink droplets, which are electrically charged and then deflected by a magnetic field to form text, graphics, or barcodes. This technology is highly reliable, enabling printing on moving products, and is suited for industries like packaging, food, and pharmaceuticals due to its ability to print on irregular surfaces and at high speeds. Additionally, CIJ printers are known for their long run times and minimal maintenance requirements.

Leibinger Sealtronic is an advanced nozzle sealing technology featured in all Leibinger continuous inkjet (CIJ) printers. Unlike conventional systems that leave the printhead open to air between print jobs—causing ink to dry and clog—Sealtronic automatically seals the nozzle and gutter in a closed loop when not printing. This prevents ink from drying out, ensuring instant start-up without cleaning, reducing downtime, and extending printer lifespan. It’s a hallmark of Leibinger’s commitment to reliability and efficiency in industrial coding and marking.

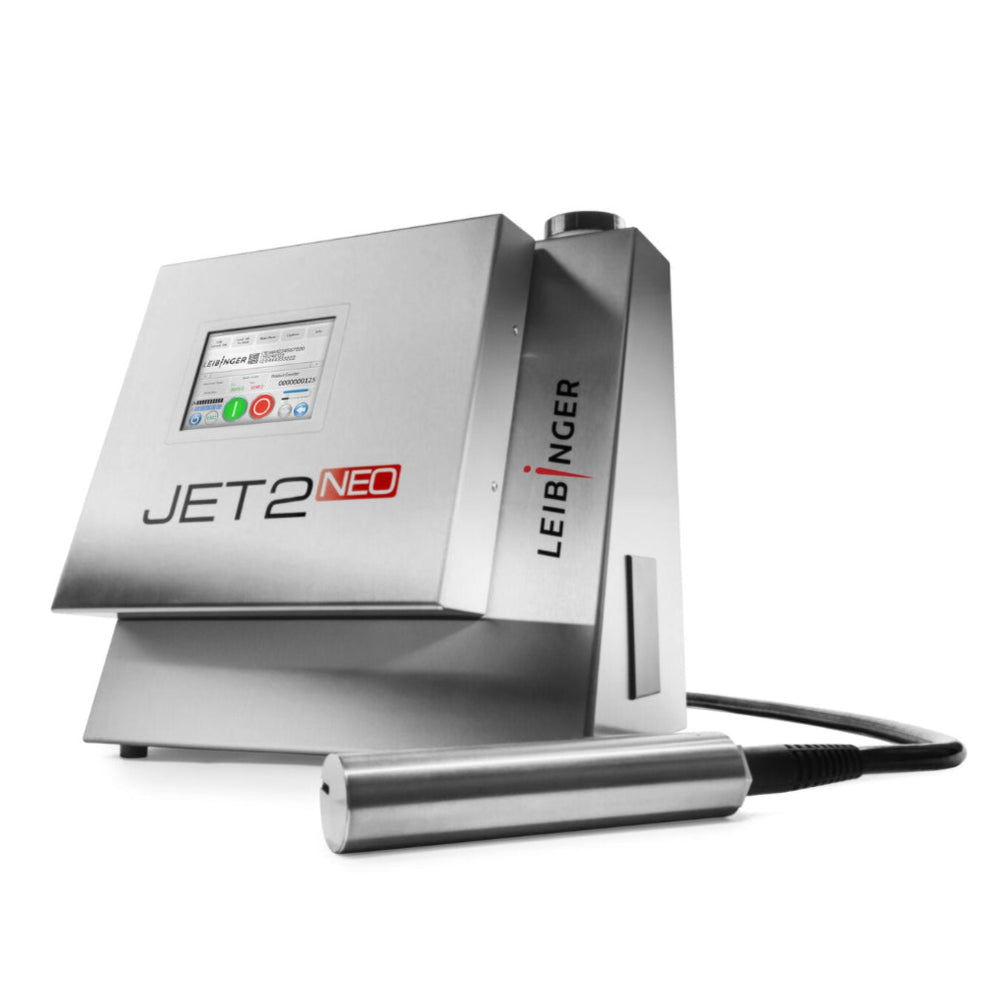

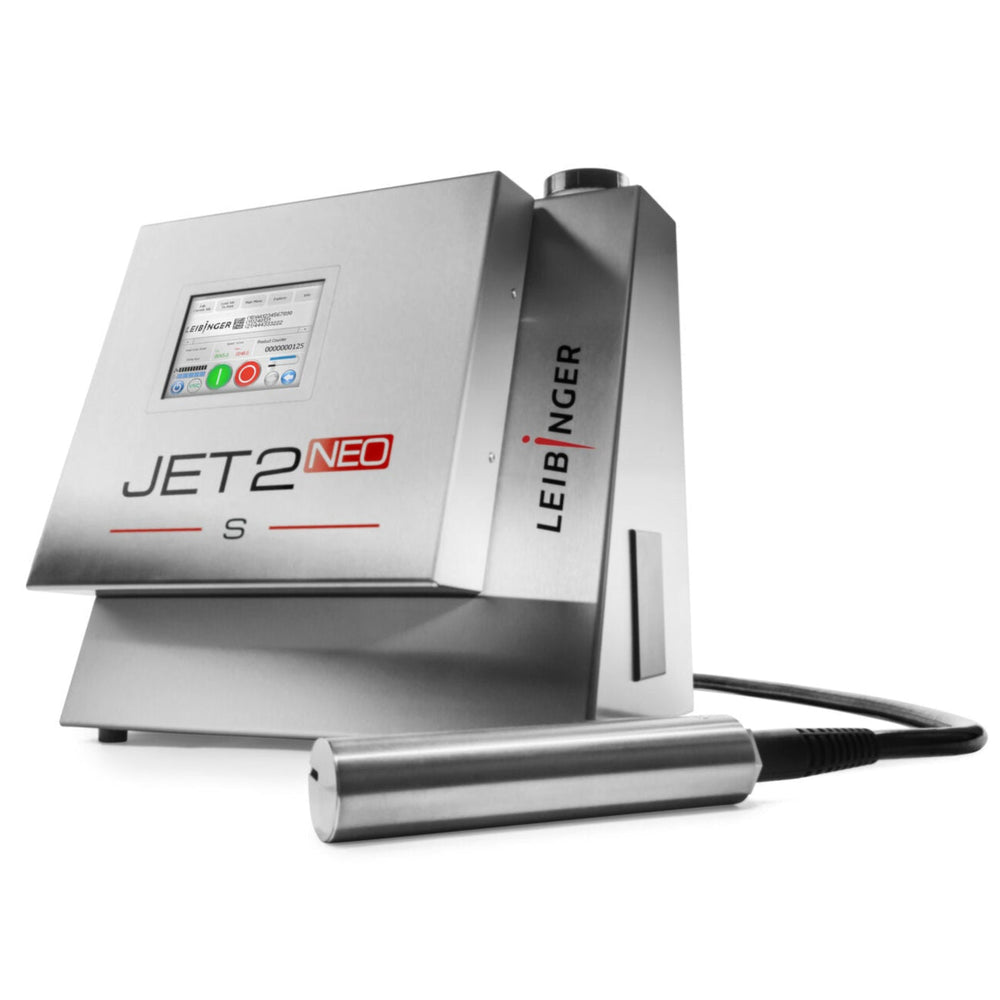

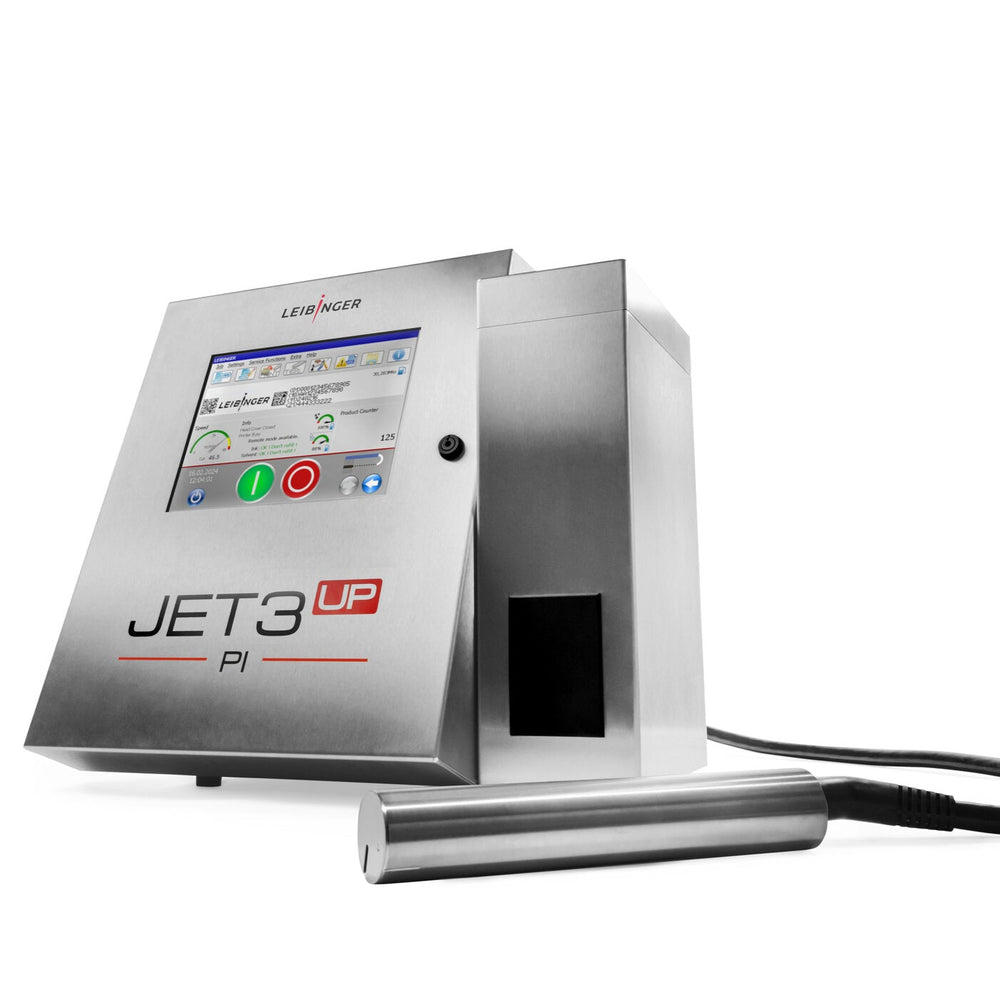

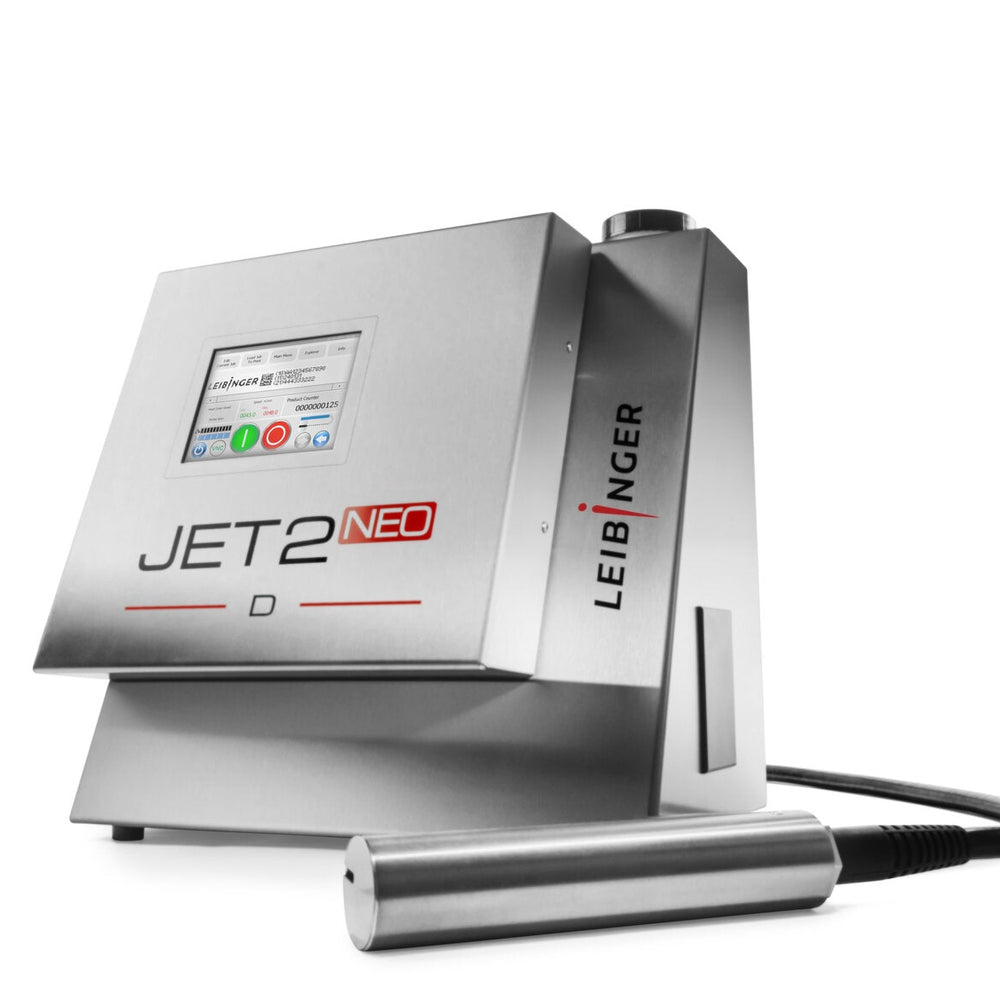

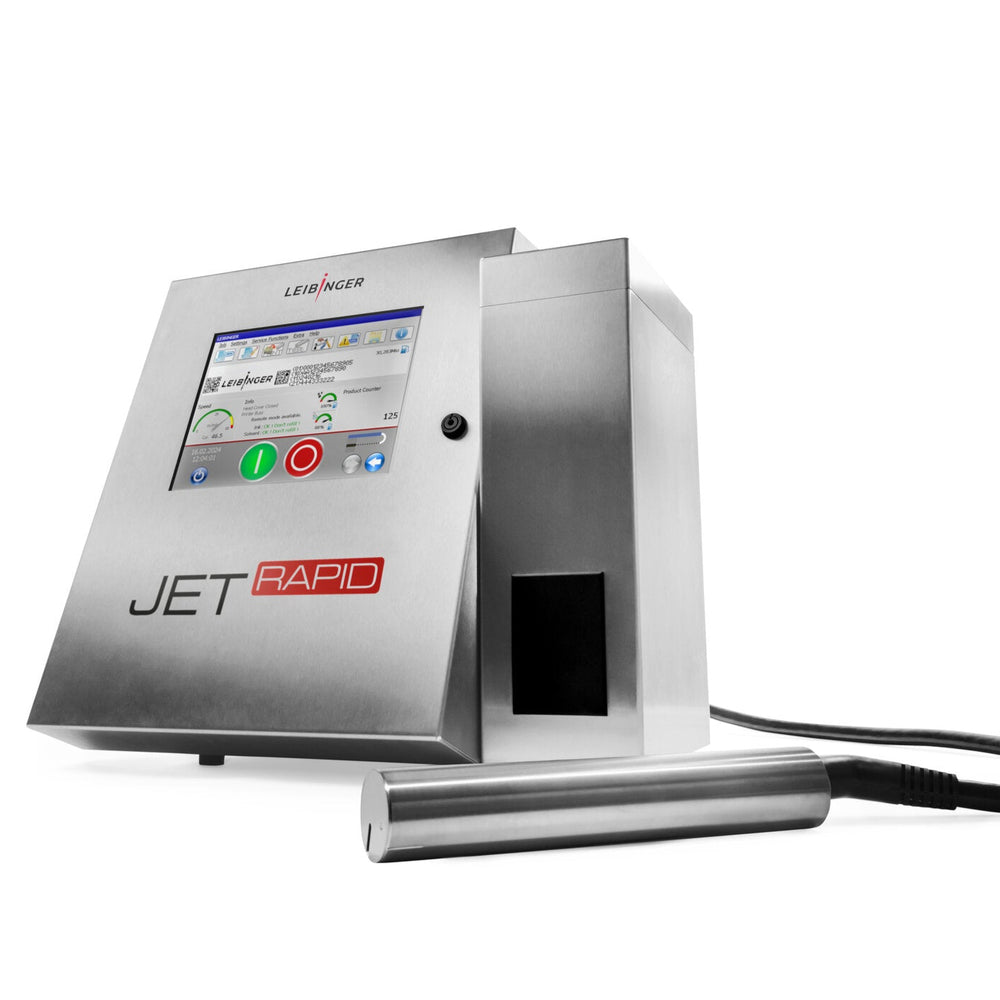

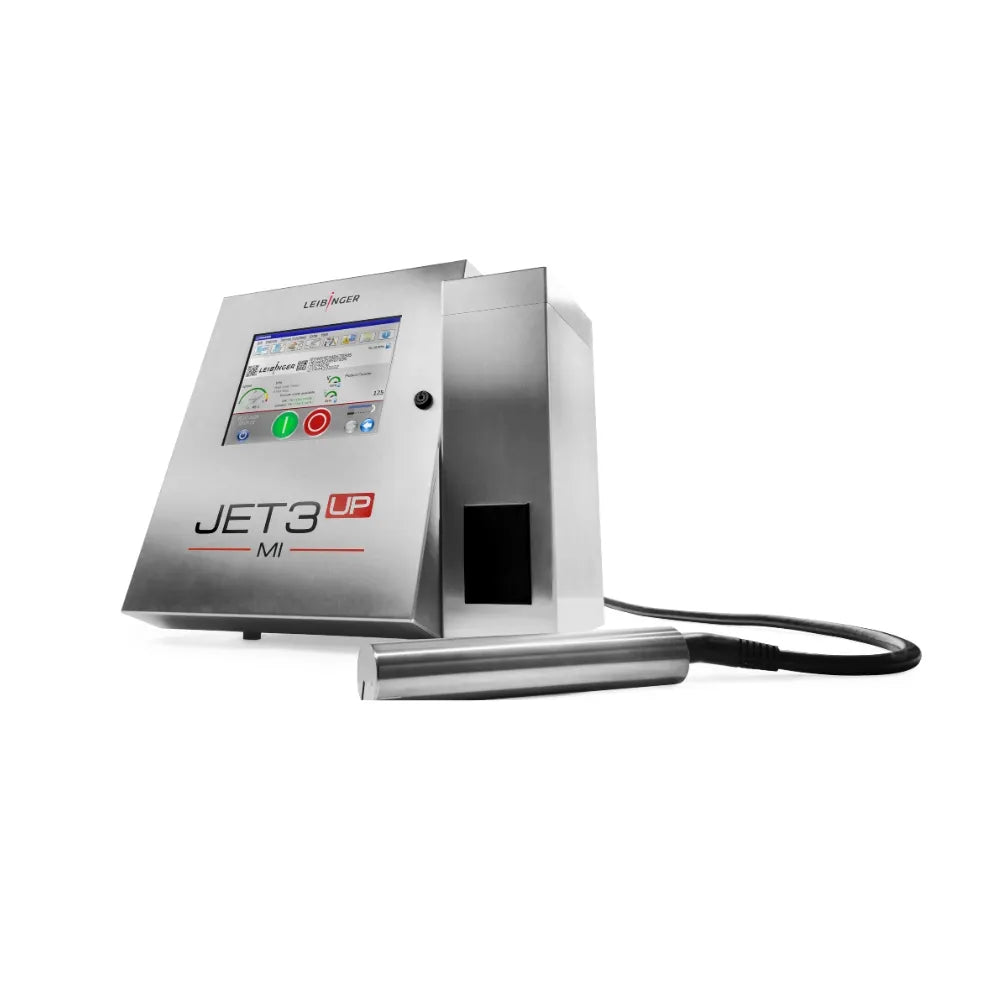

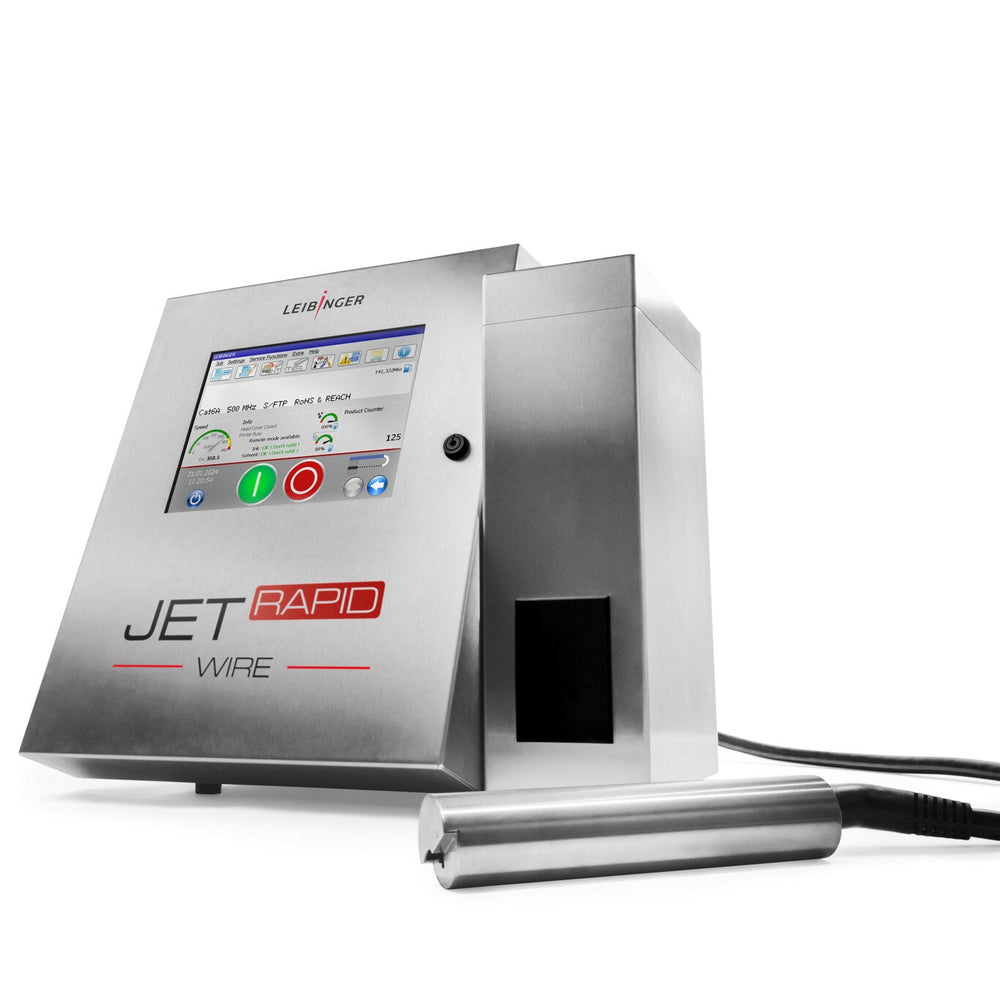

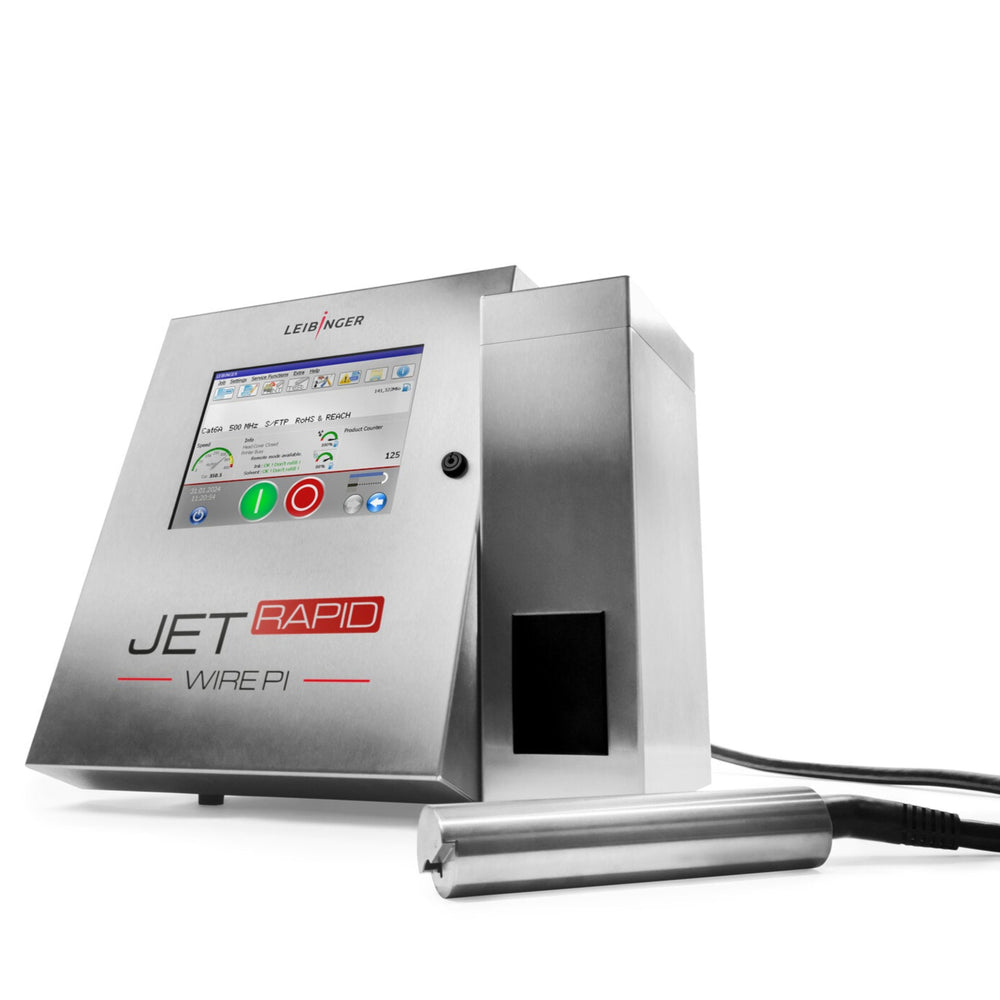

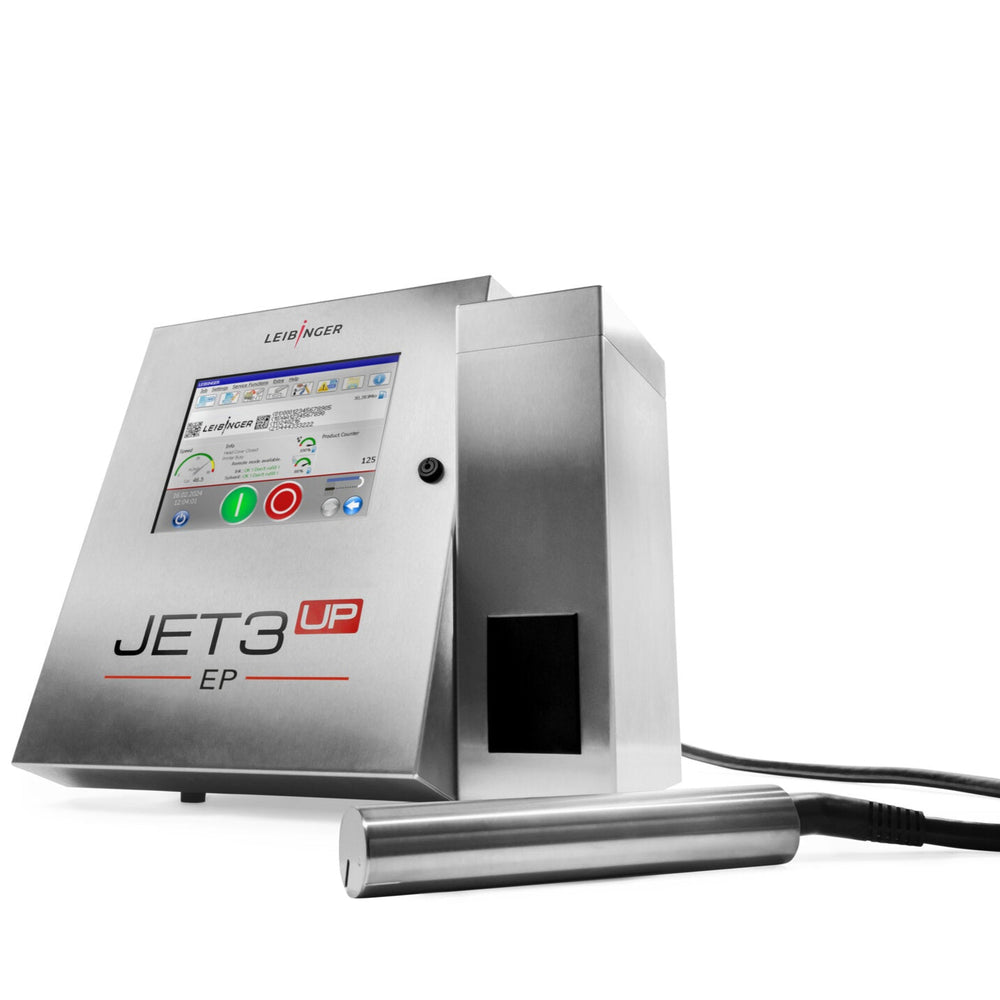

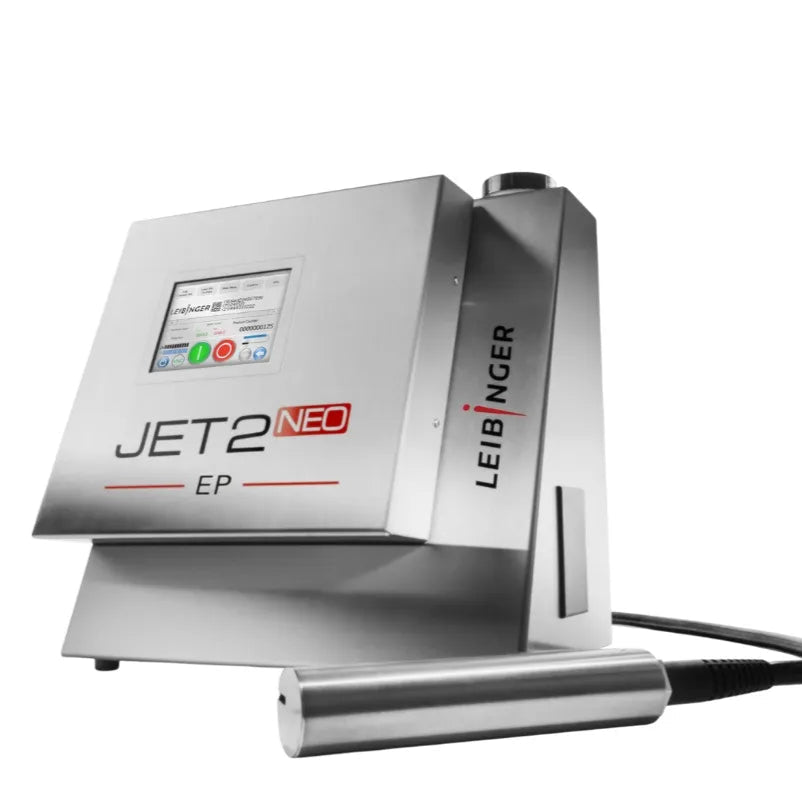

Products

Continuous & Inkjet Printing Solutions

Discover high-performance continuous inkjet printing solutions designed for today’s fast-paced production lines. Whether you’re marking packaging, bottles, wires, or industrial substrates, our continuous inkjet printers deliver reliable, high-speed coding and printing that keep your operations moving, not waiting.

Why Choose Continuous Inkjet (CIJ) Printing?

When you search for inkjet printing or ink jet printers, many results refer to office or flat-bed systems. But for industrial applications, you need a solution built for speed, durability, and non-stop production. CIJ printers:

- Utilize a continuous stream of ink droplets (rather than on-demand) for high throughput.

- They are non-contact, meaning the print head doesn’t have to touch the surface, enabling printing onto curved, moving, or irregular substrates.

- Support variable data coding, batch numbers, barcodes, and serialisation across diverse materials.

- They are built for harsh production environments – dust, vibration, wash-downs, high speed.

Key Features of Our CIJ Printers Collection

- High Speed & Throughput – Designed to keep up with fast production lines while maintaining print quality.

- Wide Material Compatibility – Print on plastics, films, metals, wires, glass, cartons, and more.

- Ease of Integration – With standard industrial controls, sensors, line encoders, and IoT connectivity for Industry 4.0 readiness.

- Low Maintenance & High Uptime – Smart fluid systems, auto-clean features, remote service diagnostics.

- Robust Coding Options – Print text, logos, barcodes, 2D/Datamatrix codes, serial numbers, and more.

- Sustainable Operations – Optimal ink consumption, minimal waste, durable codes, meaning fewer re-prints and rejects.

Applications and Use-Cases

- Food & Beverage Packaging – Print “best by” dates, batch codes, and lot numbers on bottles, cans, or films.

- Pharmaceuticals & Healthcare – Trackable codes, traceability, regulatory compliance.

- Automotive/Cables/Wires – Mark long lengths, curved surfaces, or plastics with high durability.

- Consumer Goods – Flat or curved packaging, flexible substrates, high throughput lines.

- Industrial & Heavy Manufacturing – Metals, extrusions, mouldings – challenging surfaces made easier.

How to Choose the Right CIJ Printers

- Production Speed & Duty Cycle – Match the printers to your line speed, shift duration, and downtime tolerance.

- Substrate Material & Surface – Consider ink adhesion, contrast, and durability on your material (e.g., smooth plastic vs rough metal).

- Print Requirements – Lines of text? Logos? Barcodes? Small characters vs large? Resolutions vary.

- Line Integration & Connectivity – Does the printer support encoders, sensors, PLCs, and remote monitoring for your setup?

- Total Cost of Ownership – Ink usage, maintenance intervals, consumables, and downtime all add up.

- Environment & Regulations – If you’re in food/medical packaging, containment, ink-type, or wash-down rating (IP rating) matters

Why Buy from Redemac?

At Redemac, we bring you:

- Extensive selection of industry-leading Leibinger CIJ printers and inkjet printing solutions.

- Expert consultancy to match the right machine to your line and substrate.

- Extensive service & support, we understand fast turnaround is mission-critical in production environments.

- Competitive pricing and extensive shipping options, tailored for your business.

Explore Our Collection

Browse our curated collection of continuous inkjet printers, & industrial inkjet printers filter by speed, substrate compatibility, industry, and budget. Whether you’re upgrading an existing line or installing a brand-new system, we’ve got the right solution for you.

Frequently Asked Questions

Standard inkjet (drop-on-demand) fires droplets only when needed, often at low speed and for flat media. CIJ is designed for high-speed, production-line marking, a wide range of substrates, and non-contact operation.