Redemac Inc.

Teltek InControl

See how InControl works

The four modules of InControl

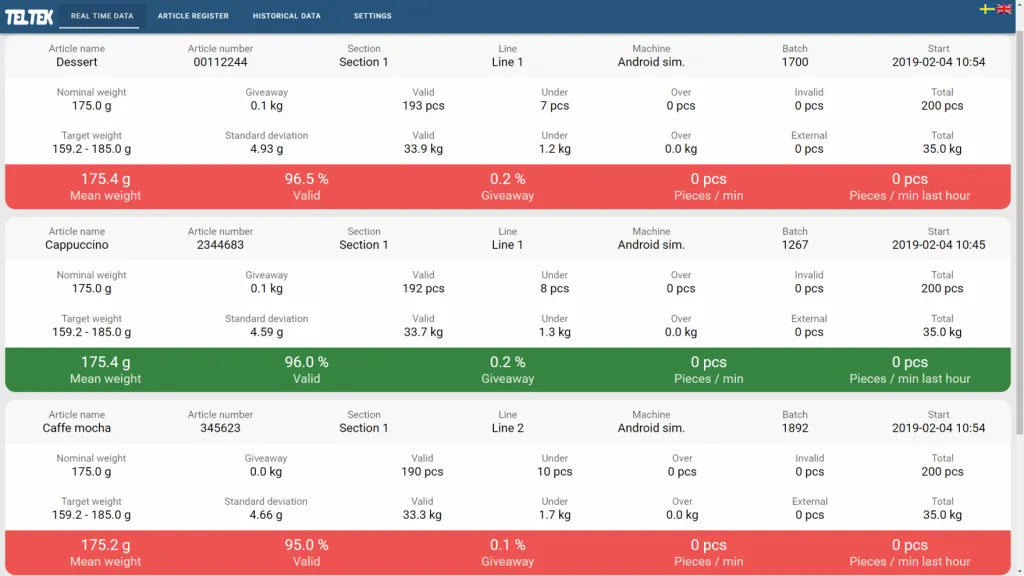

Real time data

With this module, you can overview the status of all your production lines in real time. By extracting this data, you can quickly detect and address bottlenecks.

The module offer functions for automatic overview with threshold values. If for instance a line rate of minimum 50 pcs/min is expected, InControl will signal if the rate is lower than that.

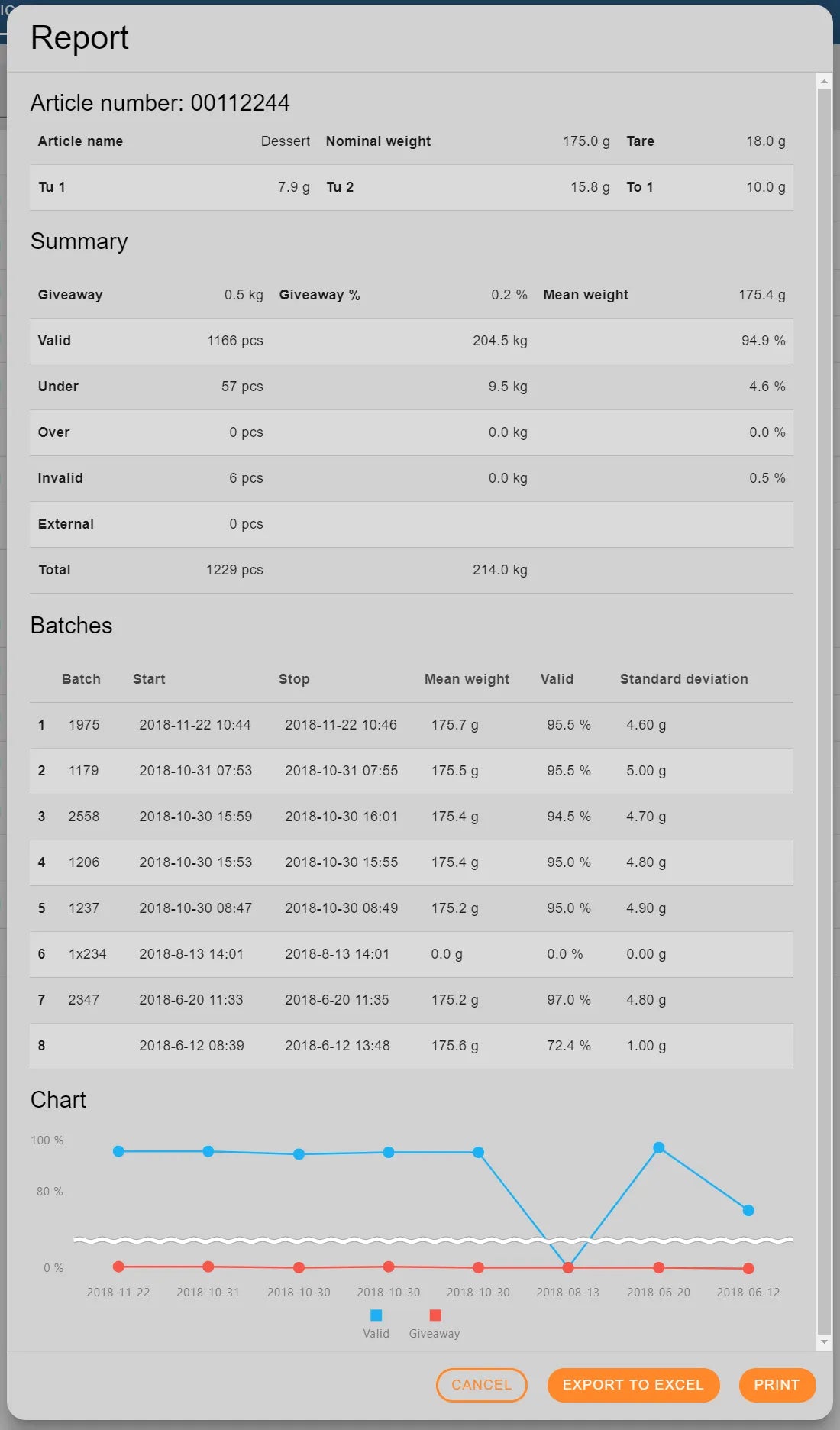

Historical data

Storage of historical production data will enable overviews of historical performance and development. It is also possible to look at specific dates and batches.

When the data is extracted, it is analyzed and compiled after your preferences. This helps you to obtain a clear overview.

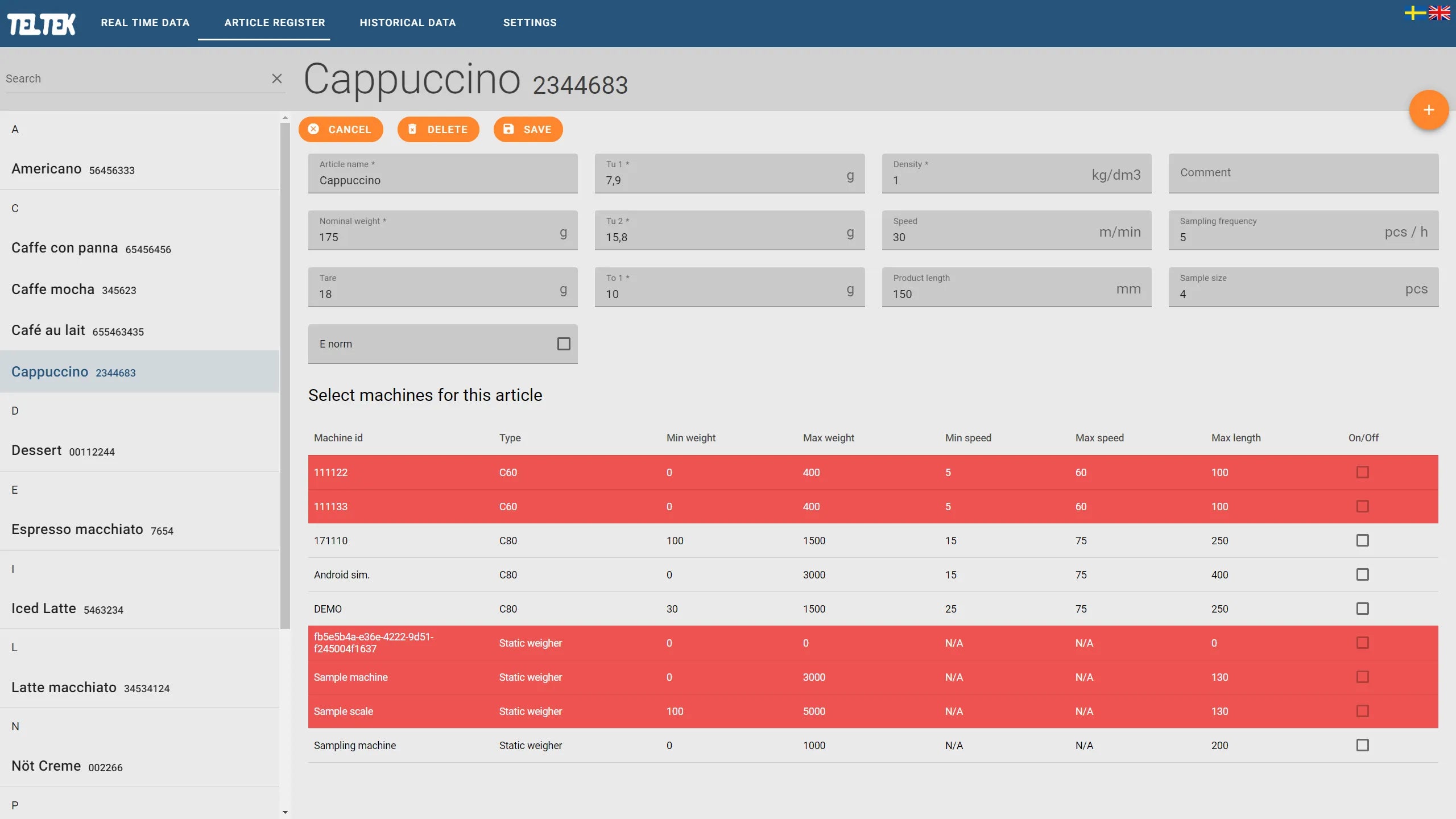

Article register

The Article Register module is a centralized and user-friendly article register where users can add, change or remove product settings. When you are going to produce a product stored in the article register, only a few button presses are required for the checkweigher to access the right settings.

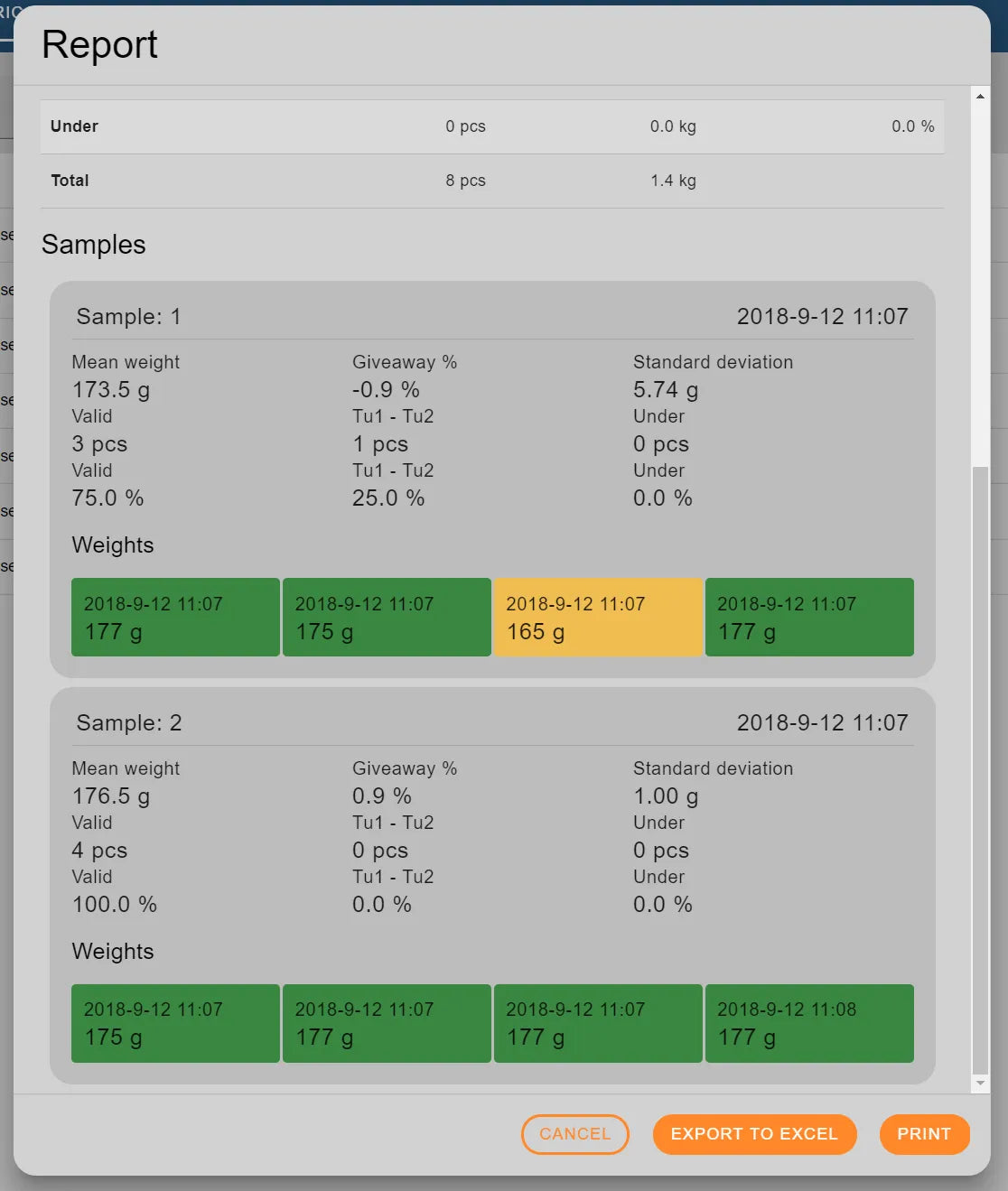

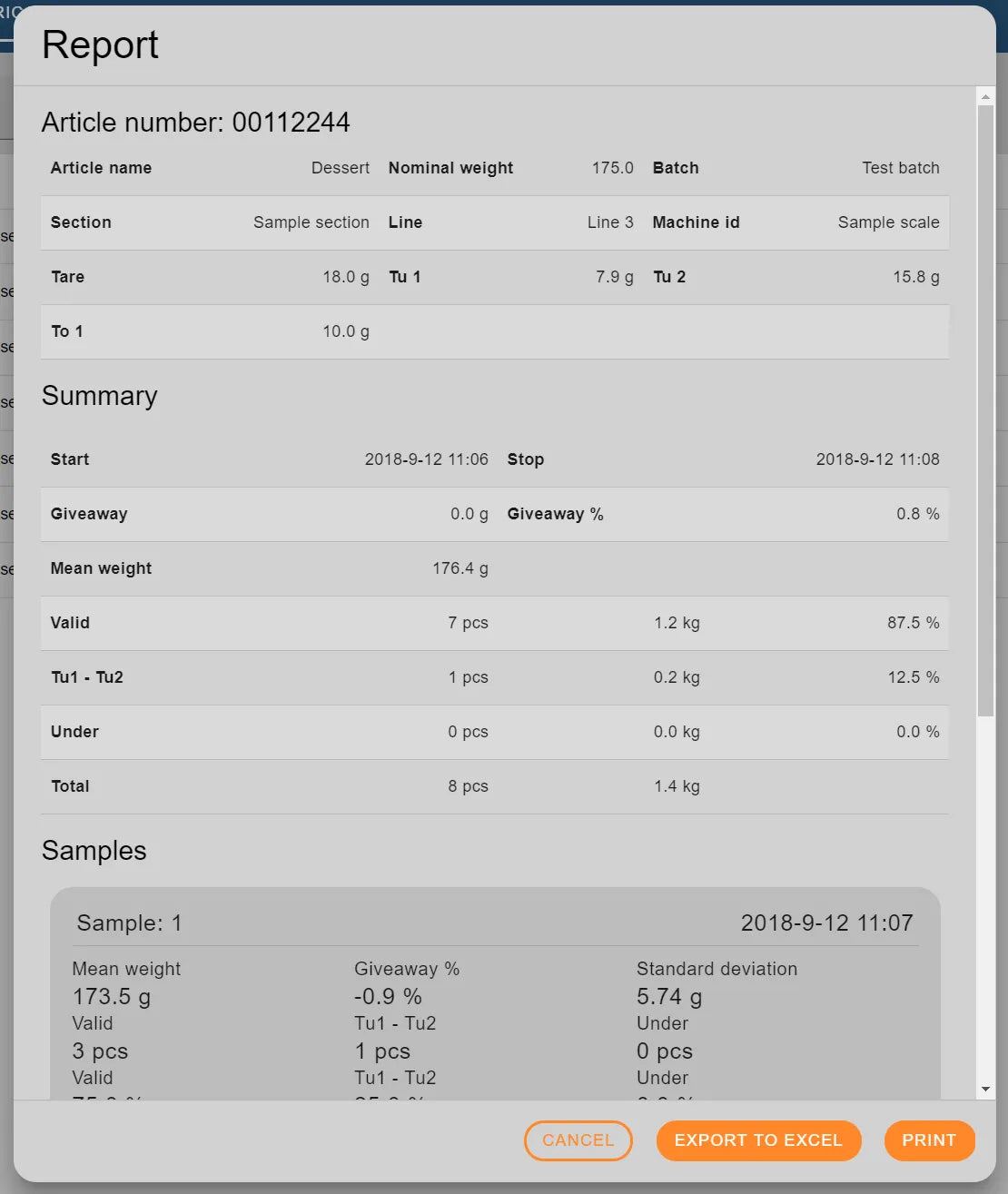

Samples

InControl sample is an effective tool for recording, storing and presentation of sample weights.

With InControl Sample module, a simple station consisting of a static weigher and a connected PC can be used as a mutual weighing station for several production lines. In the module, you choose how many sample to be weighed per event, and how many times sample weighing shall occur per hour. The system keep track of the production and will signal if a sample is late.