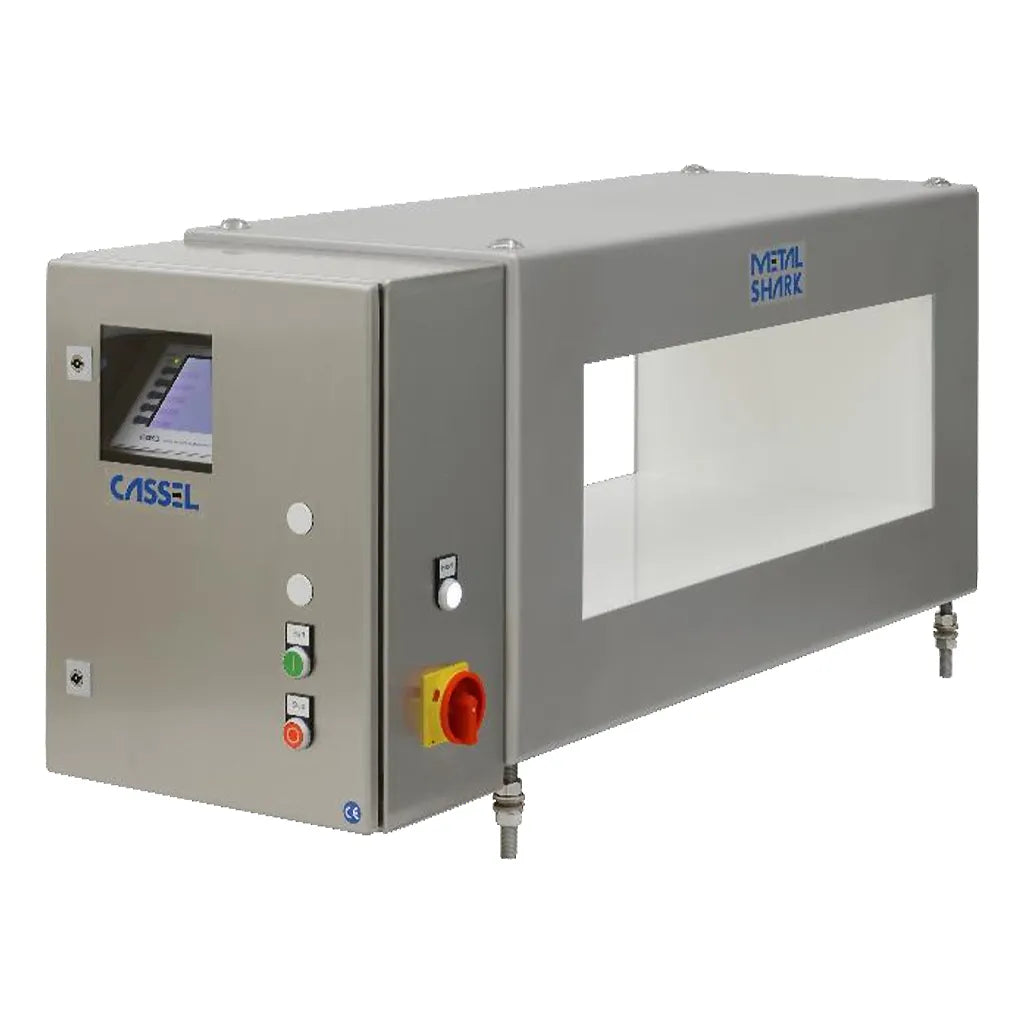

Cassel

Metal Shark® BD

Features

- Reliably detects metals in packaged and unpackaged goods on conveyor belts

- Very high sensitivity in dry, moist, salty, or frozen goods

- Easy setup and intuitive operation due to auto calibration and wizard guidance

- Maintenance-free design with automatic and continuous calibration of detector coils

- Compliant with food safety standards (IFS Food, HACCP, BRC*)

*BRC-Kit

With this option, the device meets the requirements of the British Retail Consortium (BRC) Global Standard for food safety and thus also the common standards for HACCP and IFS.

Included

- Sensorhead BD

- METAL SHARK® Controller

- Optional: Customized conveyor system

- Optional: wide range of reject devices

Accessories & Extras:

- High temperature version

- Versions for hose cleaning (LPW) or cleaning with high-pressure cleaner (HPW) possible

- SHARKNET connection for automatic documentation according to HACCP, IFS or BRC standard

- Separate mounting of the control unit (e.g. wall mounting)

- Signalling devices (optical/acoustic)

- Performance Verification Certificate (proof of functionality for audits) by CASSEL service e.g. during commissioning or maintenance

- BRC-kit for a fail-safe system (MD failure, ejection failure, ejection box full, air pressure failure) including product jam monitor, required covers, ejection, container and compressed air monitoring, product counter etc.

Application:

- Monitoring of packed or loose goods free or on conveyor belts or chutes

- Quality assurance for incoming goods, outgoing goods or during running production

Industries:

- food, petfood

- chemicals, pharmaceuticals and hygiene

- paper, cardboard, packaging

- textile and fleece

- wood, recycling

3D-Detection:

BOOST FACTOR:

Up to 50% more accuracy - METAL SHARK® detects stainless steel up to 1mm smaller compared to conventional detectors.

CASSEL’s unique 4-Quadrant-Technology has evolved to the 3rd dimension. The MultiPhase and BOOST FACTOR technologies add multi-phase measurement and signal amplifying factors to this established technology and thus create 3-dimensional signal models of your products signatures - as unique as a fingerprint.

MultiPhase:

Continuous adjustment to changing conditions for even more stability. The METAL SHARK® can easily cope with frozen or heated products, changing product orientations or temperatures as well as cooled, heated or humid environments.

Customization

The METAL SHARK® BD metal detector can be individually adapted to the requirements of your products, production lines or hygienic requirements. Increased documentation requirements can be handled via the SHARKNET®.

If you need to ensure certain sensitivities, send us samples of your products and we will adapt the device perfectly to your requirements.