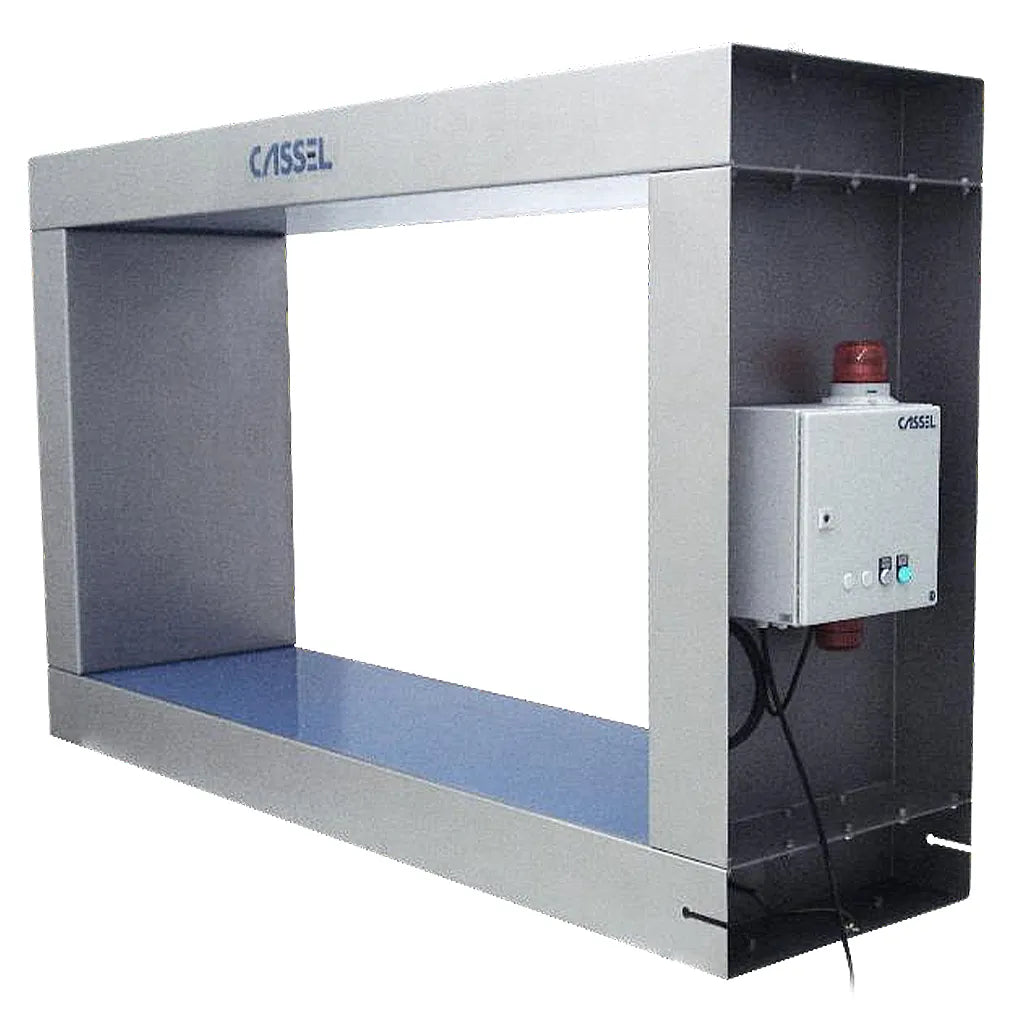

Cassel

Metal Shark® TU

Highlights

- 4-Quadrant technology provides maximum detection performance with the highest available reliability in the detection space

- Simple setup with TeachAssistant

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password system, automatic log out upon timeout

- Documentation of all events and metal detection alerts

- IFS and HACCP reports available on the display at the touch of a button

- Optional: data transfer to USB interface or connection to the company network via

SHARKNET® software - Cyclical function monitoring with Performance Validation System (PVS)

Features

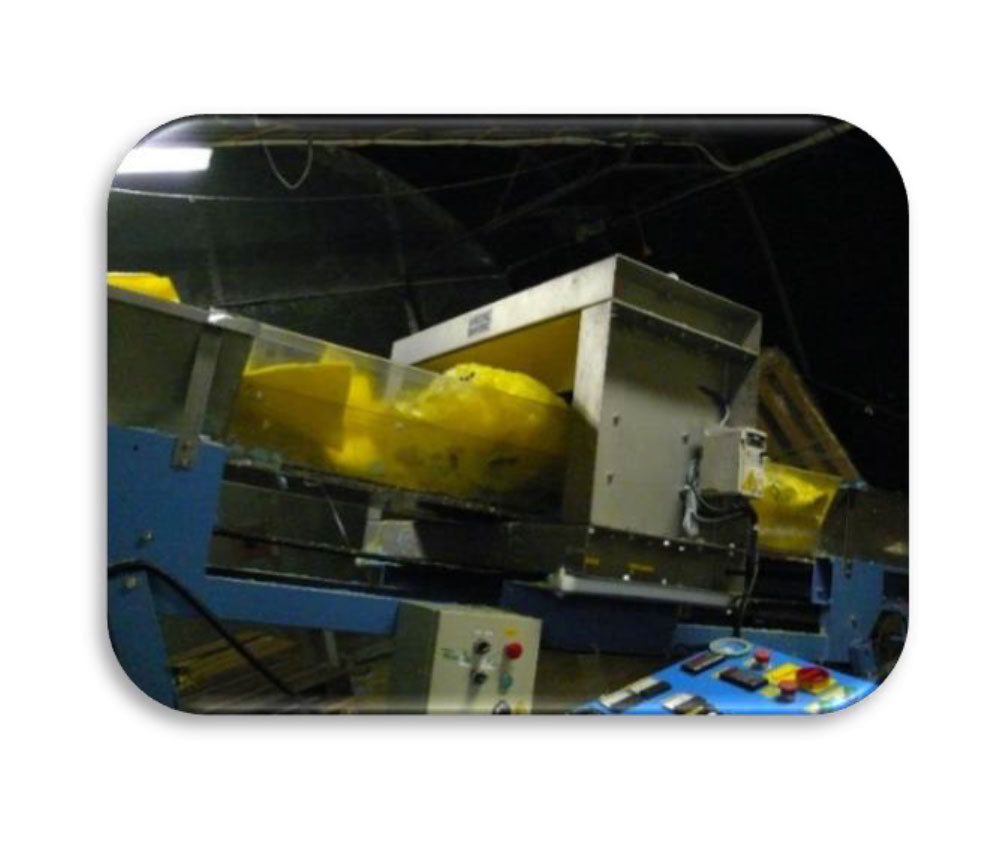

- Reliably detects metals in packaged and unpackaged products on conveyors

- Removable sides make it particularly easy to install, ideal for belts that cannot be split

- Highest sensitivity with 4-quadrant technology

- Automatic calibration and TeachAssistant for intuitive control and easy installation

- Maintenance-free due to automatic balance and calibration control

Industries

- Pet food

- Recycling

- Paper, cardboard, packaging

- Chemicals and pharmaceuticals

- Textile and fleece

Accessories & extras:

- High temperature version

- Versions for hose cleaning (LPW) or cleaning with high-pressure cleaner (HPW)

- SHARKNET® connection for documentation, control and maintenance from a PC

- Signalling devices (visual/acoustic)

- Performance Verification Certificate (proof of functionality for audits) by CASSEL service technicians, e.g. during commissioning or maintenance

Applications:

- Monitoring of packed or loose goods or on conveyor belts or chutes

- Quality assurance for incoming goods, outgoing goods or during ongoing production

- Machine protection, e.g. in the recycling industry