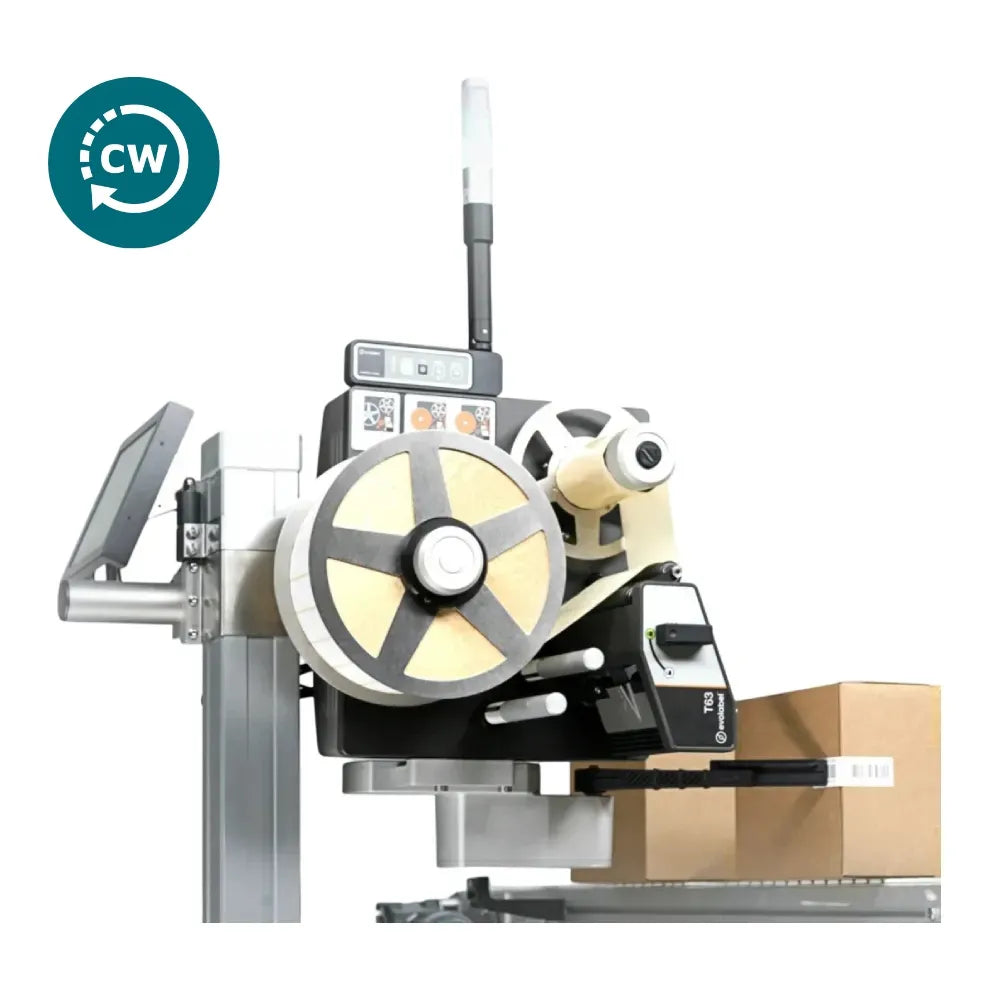

Evolabel

Wipe90 G2 Applicator

Adjacent side or corner wrap labeling

The pulse encoder controlled stepper motor driven applicator arm makes both adjacent side labeling as well as corner wrap easy. Profiles function in the software allows linking various labeling requirements (like font apply only and front+side apply) to specific products. The Wipe90 G2 applicator suits all Evolabel printer models, from the D43 to the T63 model.

Full flexibility

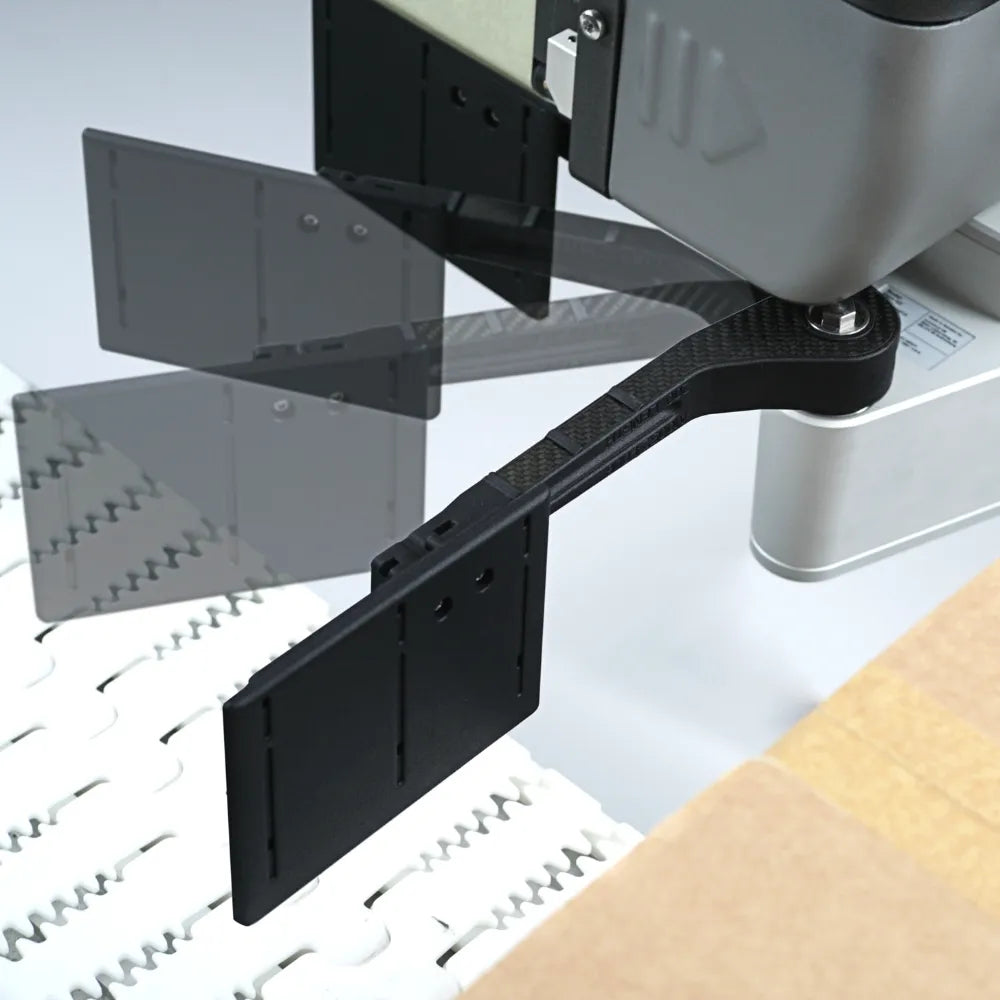

The light 3D printed arm, stabilized by carbon fiber, is available in various lengths; from 200 mm to 400 mm. The Wipe90 G2 applicator can be mounted to apply products coming from right or from left. The applicator can also be set up to make a 180 degree stroke, simplifying access to the label handling in some applications.

The Evolabel Wipe90 G2 applicator is developed with ease of use, reliability, and safety in focus. It is fully automatic and no daily adjustments or calibrations are needed. The applicator works with a rotational, step motor driven motion and is built with the Evolabel patented applicator pad range to achieve optimal label handling. The patented pads create vacuum locally by feeding compressed air from the applicator.

The Wipe90 G2 can be mounted on all Evolabel printers and is easily mounted with two screws, a tube for compressed air, and an eApplicator cable for the electronic interface. There are two mounting options for the Wipe90 G2, standard and alternative mount. The most suitable mount depends on the product conveyor's direction, for more information see examples of usage below. It is also possible to invert the applicator motor position if the space is limited around the applicator.

The applicator is controlled by the printer, normally by using the signal from an external photo sensor as a direct input to detect the product to be labeled.

A print and apply application with a Wipe90 G2 normally feeds the labels vertically downward with the printed side facing left or right relative the product conveyor's direction, see figure below.

The Wipe90 G2 applicator is designed for print and apply applications with high performance; primarily corner wrap front-side labeling or side and/or front labeling. The applicator can be equipped with a motorized stand to handle batches with varying product heights and label positions.

The applicator has a standard arm length of 200 mm and handles labels with sizes from (30‐118) x (20‐150) mm with D43/T43 and (115‐176) x (20‐150) mm with T63.

Selecting Wipe90 G2 Standard or Alternative mounting depends if the product travels from Left or from Right.