Cassel

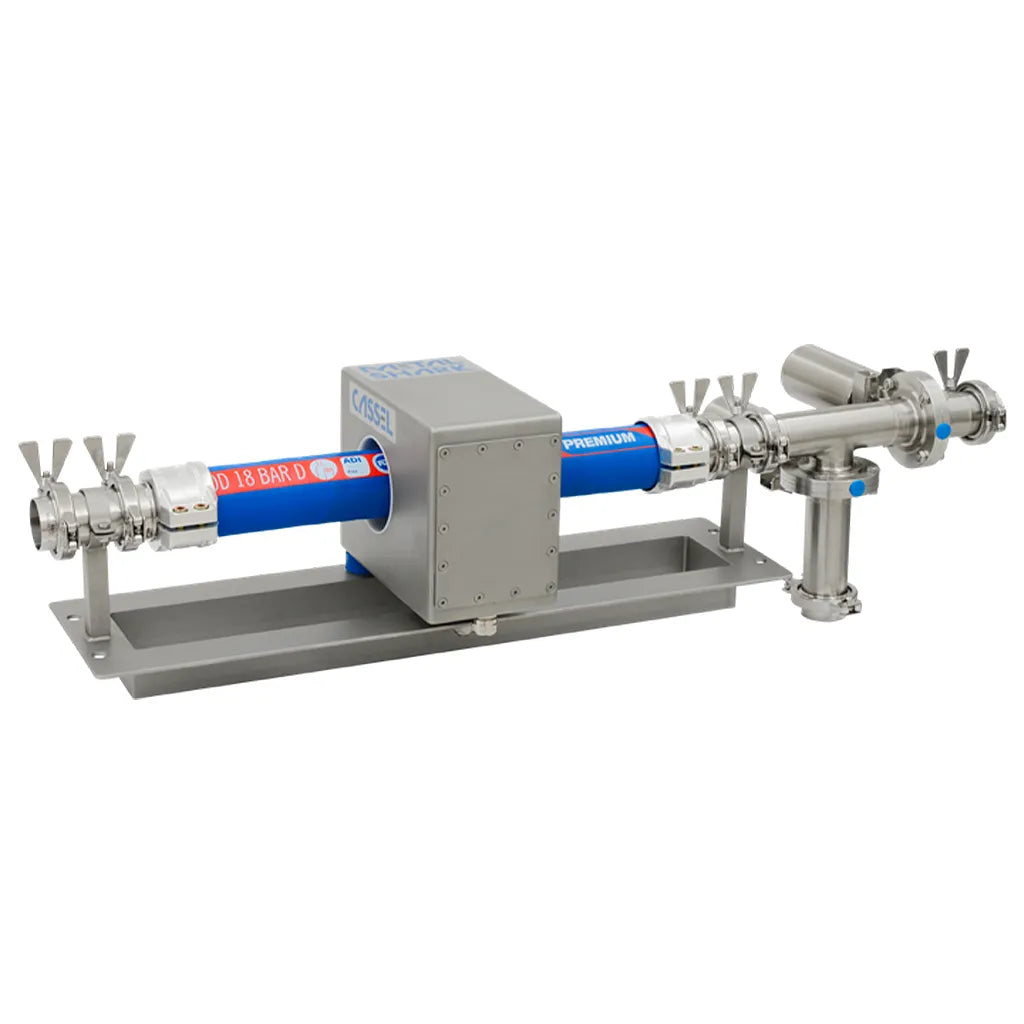

Metal Shark® In Liquid

Highlights

- Reliably detects metal contaminants in liquid and pasty products

- Easy to integrate into common pipeline systems from 1 in. – 6 in.

- Stainless steel housing and frame are easy to clean, supplied tube is CIP-capable (Cleaning In Place)

- Intuitive control and easy installation through autocalibration and teach-in wizard

Features

- 4-quadrant technology provides maximum search performance with high reliability

- Simple setup with TeachAssistant, preset product types like salty, sweet, wet, dry etc.

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password system, automatic log out after time lapse

- Easy to integrate into common pipeline systems

- Documentation of all events and metal messages

- FS5 and HACCP reports available on the display at the touch of a button

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

- Cyclical function monitoring with Performance Validation System (PVS)

Application

- Monitoring of liquid or pasty products in pipes between pump and filling station, e.g.

- soups and sauces,

- ketchup and mayonnaise,

- edible oil or processed cheese,

- creams, toothpaste and much more.

- Sausage or meat fillings are possible (see also METAL SHARK® IN MEAT)

Industries

- Food processing

- Chemicals and pharmaceuticals

Accessories & Extras

- Versions for hose cleaning (LPW) or cleaning with high-pressure cleaner (HPW) possible

- SHARKNET® connection for automatic documentation according to HACCP, IFS or BRC standard

- Signalling devices (optical/acoustic)

- Ensuring the functionality by autotest or simple test port for manual insertion of the testball

Rejects

Two different valve types, optimally matched to the respective product, guarantee reliable discharge of metallic contaminants. All valves can be CIP cleaned.

| Butterfly-/Shim valve EX-BF | Arc valve EX-BOG |

|---|---|

| For liquids and slightly pasty products | For viscous, pasty products |

| Very stable | For liquids with solids in it |

| Pre-opening on ejection side prevents recoil into pipeline | For pressure up to 40 bar |

| Low cost version | Cip-cleanable and free from Dead spaces |

| For pressure up to 8 bar | Suitable for cleaning with a Cleaning pig |

Hoses/tubes and connections

- food safe pressure hose, applicable up to 6 bar with steam up to 164°C

- Pipe made of polyoxymethylene (POM) for operating pressure up to 40 bar

- Connections selectable from milk thread, Tri-Clamp or SMS couplings

- available in all common sizes: hose from 1"/25 mm to 4"/100 mm, pipe up to 6"/150 mm

METAL SHARK® IN Liquid Self-Monitoring (optional)

Metal detectors are critical control points in every production line and the components connected to them should also be continuously monitored

| Material | Properties |

|---|---|

| Compressed Air Monitoring | Reports an error if the air pressure is too low for the functionality of the sepa flaps. |

| Reject Monitoring | Warns if the reject unit has not switched correctly after metal detection. |

| Testport | Simple version, without BF valves, only one tube with sealing cap (Tric-lamp) for inserting the test ball, incl. test bodies |

| Testport Check & Catch | Tube with sealing cap for insertion of a test body and wide ejection valve (stainless steel 1.4404 / AISI316L, IP65) to ensure the flow of material during function test |

| Autotest | Functional test that does not require opening the product pipelines: Test pieces (FE/NFE/VA) are moved with compressed air through a separate test tube. The control unit indicates which sphere sizes are to be tested. Incl. push button for FE, NFE and VA testing, pneumatic valve, test specimen. |

| Test Balls | Test balls, diameter 10 mm made of plastic POM, with embedded metal ball made of iron, brass and stainless steel, certified. Ball size, metal type and certificate number are embedded in the test ball. |