IHRESS

i600TP

MODELS TO CHOOSE FROM

i600TP-F Model

Front loading

i600 TP-L Model

Side loading

FMA carriage

Adjustable mecha- nical film brake with foot trapping safety

PEM carriage

Powered pre-stretch 300% with foot trapping detector (recommended option)

Special environments

Explosives: ATEX Temperatures below 0ºC

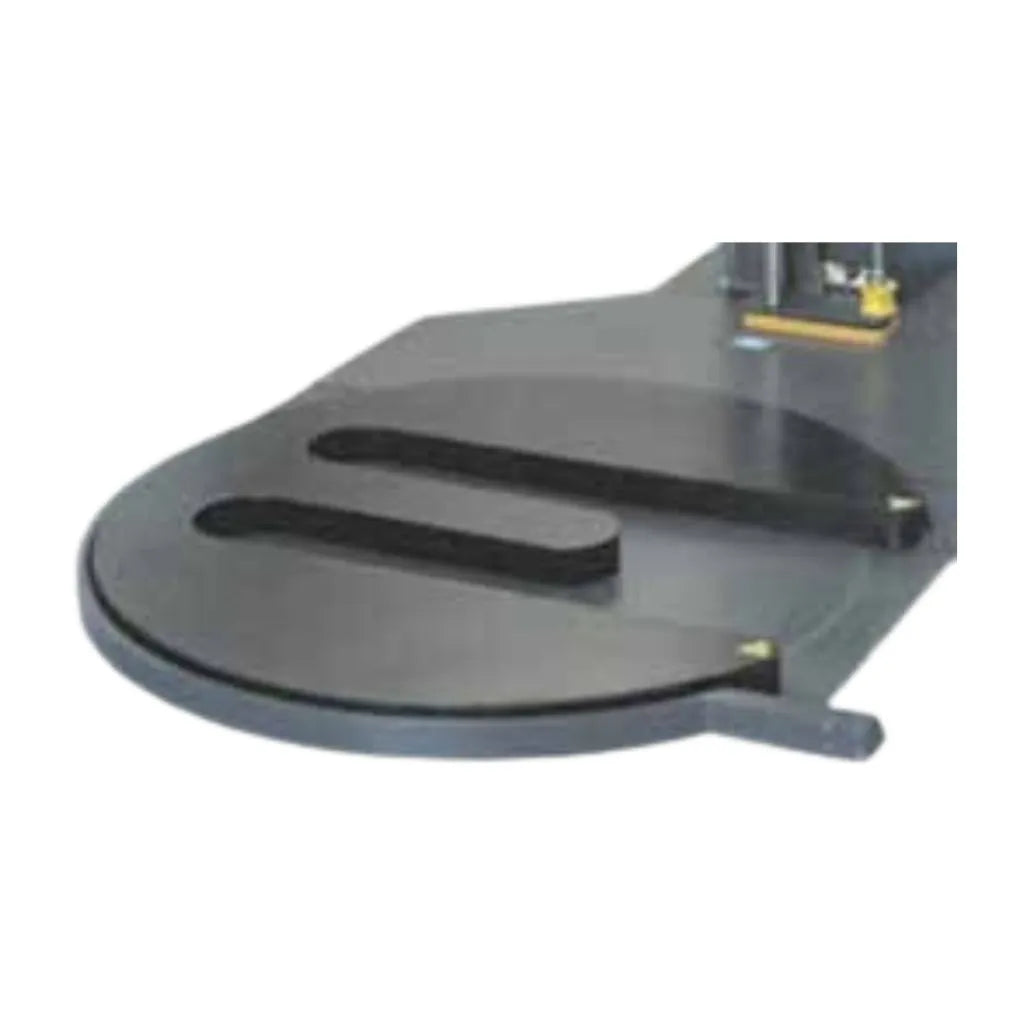

Powered top platen

Machine with powered top platen included for light or unstable loads

OPTIONS AND ACCESSORIES

1. Direct film brake

2. Mechanical film brake (standard)

3. Electromagnetic brake

4. Powered pre-stretch film 300%

5. Twin film holder

6. Powered top platen

SPECIAL CUSTOMIZATION ON DEMAND

• Ultrasonic detector for black loads

• Stainlees steel 304

• ATEX explosive environments

• Special heights

• Special platforms

• Different pre-stretch ratios 150%, 200%, 300% or 400%

• Carriages for 750 mm or 1.000 mm height film

• PLC extended up to 10 programs