IHRESS

iTRM1500

Options And Accessories

Powered top platen

It holds the load at the top of the pallet without deforming it while the pallet is being wrapped avoiding the risk of the product collapse.

Top cover dispenser iTDM1800 (Optional)

Accessory which allows to dispense a cover of film to do a complete wrapping. Depending on the position and the functioning cycle of the machine, the wrapping will provide a dust or rain protection.

Top Cover Dispenser iTDM1800

TRM1500 turntable with motorized chains conveyor (Optional)

The turntable of the machine can include a chains conveyor (3 or 5 chains depending

on the size and type of pallets to be wrapped), which is necessary for a side transportation of the pallet.

Special environments (explosive environments, corrosion, sub-zero, …)

We have experience and we can provide proven solutions for explosive environments (ATEX), corrosive environments (Stainless Steel) or sub-zero temperatures (down to -30 ºC).

Motorised pre-stretch

Motorized pre-stretch carriage 300% (fixed prestretch ratio) with anti-entanglement and roping system (Optional: 150%, 200%, 400% pre-stretch).

Motorized pre-stretch up to 300% (variable prestretch ratio) with roping system and electronic regulation (optional).

Roping system: this feature provides a rope which can be programmed at different heights of the load to reinforce and stabilize the pallet. Recommended for unstable loads or loads in layers.

3ALL System

Thanks to this system, the 3 independent external mechanical elements are replaced and integrated in just one single unit, which performs the same 3 functions: clamping, cutting and dolly heat sealing.

Also, a rope in the film is made in the final stage, which allows the heat sealing of any kind of film (stretchable, microperforated, etc.) and with any thickness, thus avoiding the loose tail of film which appears without this system.

This system also avoids its mechanical maintenance, as it does not have any obstacles.

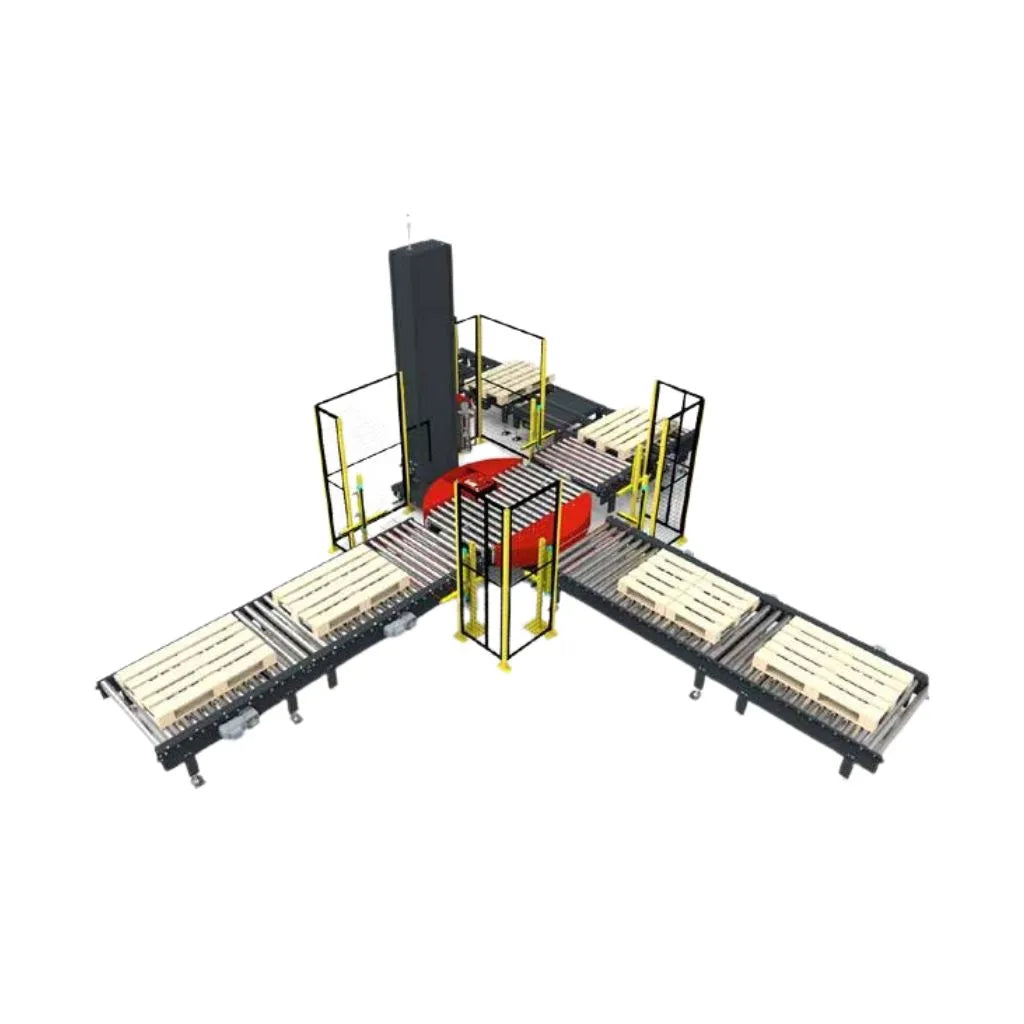

Automatic stretch wrapping line

with motorised roller conveyors