STANDARD MACHINE TECHNICAL CHARACTERISTICS

· Powered film carriage with variable speed, placed sidewise.

· Powered pre-stretch 300% with foot trapping detector

· Automatic load height detection by photocell.

· Soft start/stop by SCHENEIDER frequency inverter with return to start position

· Pneumatic clamp to hold film before the wrapping cycle.

· Automatic film cutting arm.

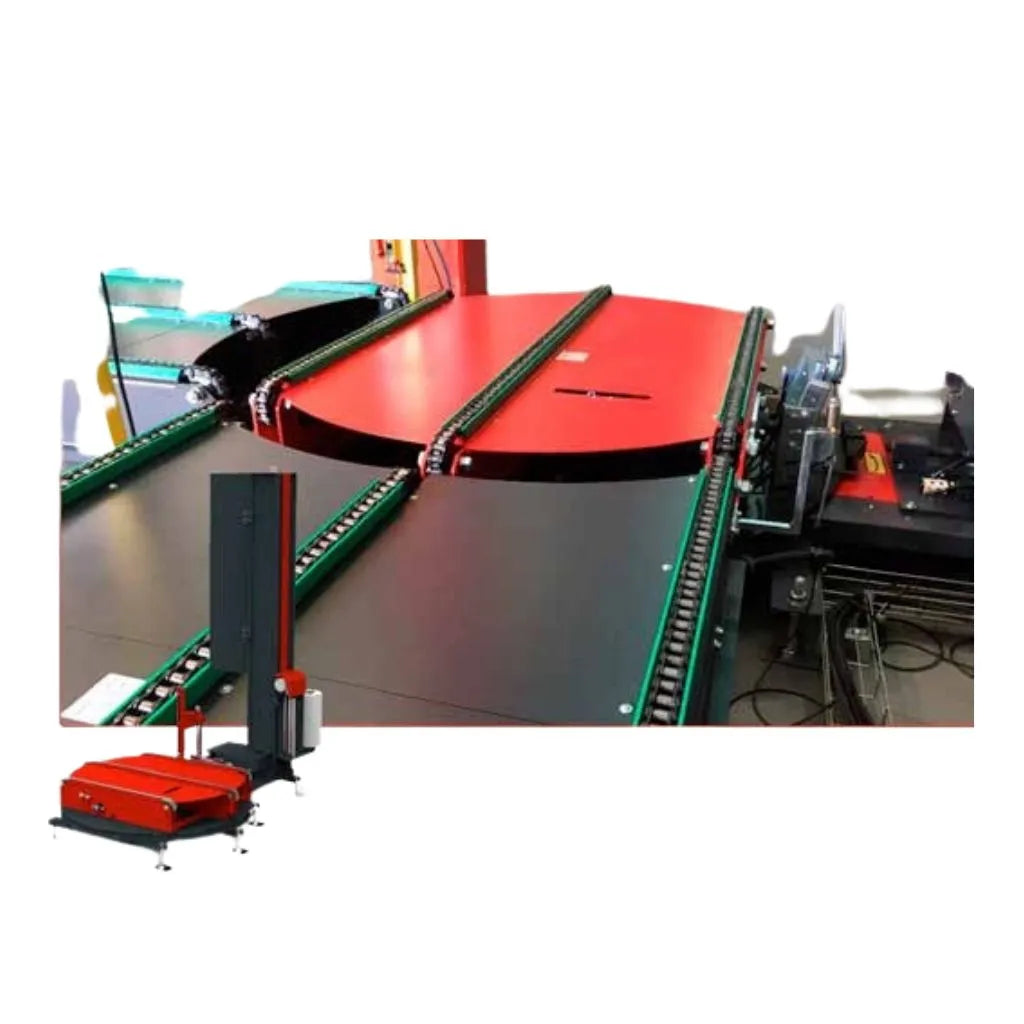

· Turntable with motorized rollers conveyor

· Turntable with motorized 3 chains conveyor (optional)

· Wrapping cycles counter.

· Reinforcement wraps at any point in the cycle.

· Controlled by PLC SIEMENS

· HMI touch screen.

· Up to 20 pallets/hour (variable output depending on the load features, number of wraps, etc.)

· 10 Programs customizable by the user: lnitial, top and bottom wraps, upper overlapping timing,

cycle types, etc.