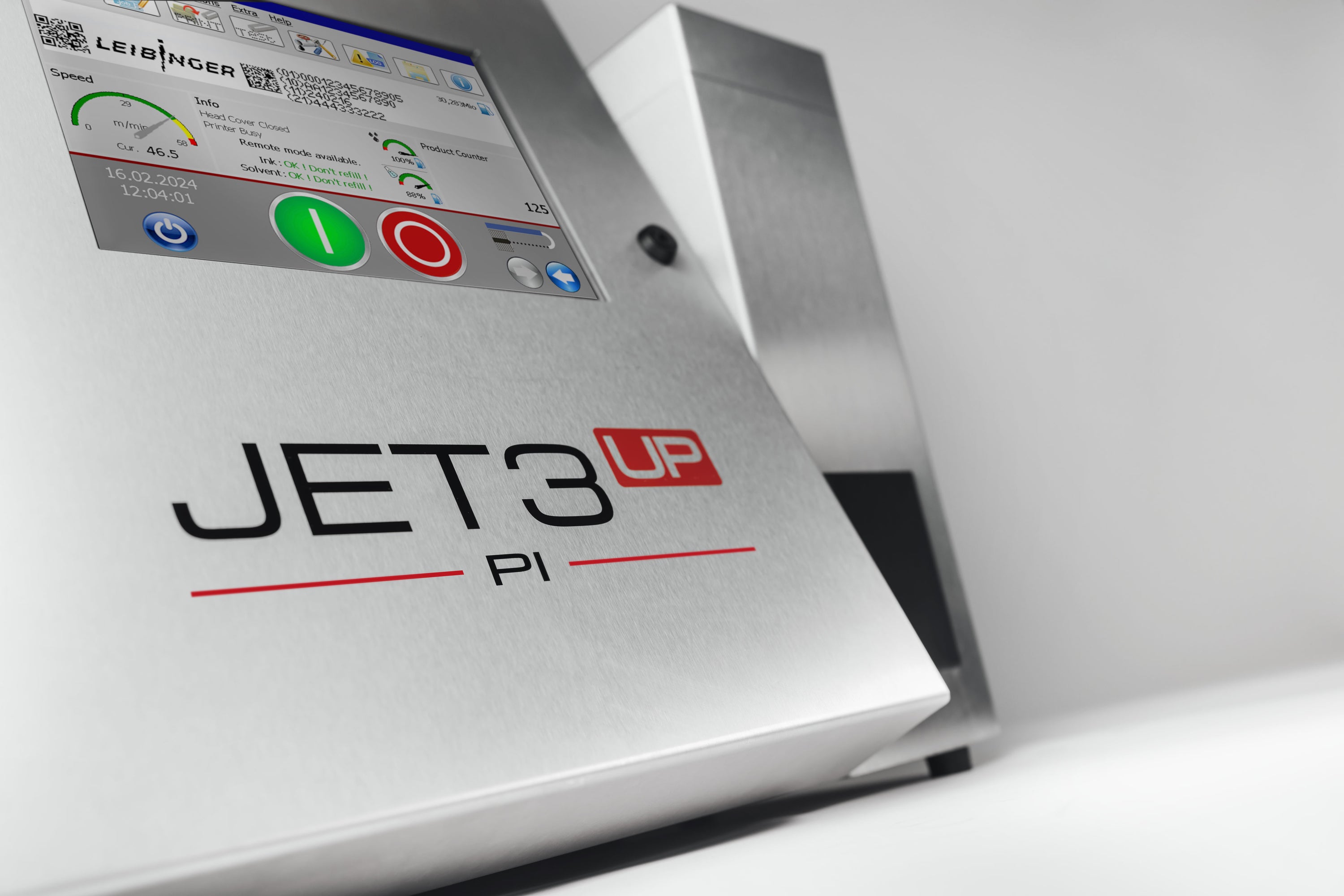

leibinger

JET 3UP PI

Do you want to mark dark surfaces in high contrast with a LOT number or meter marking? Then you need an inkjet printer that can process pigmented inks (also known as contrast inks or opaque inks) to create a good contrast level on the product. After all, it is just as difficult to read conventional inks on dark backgrounds as it is to read writing from a fountain pen on black paper.

The challenge: Pigmented inks cannot be used in a standard inkjet printer. This would result in problems in short order because the pigment in the contrast inks would continuously build up in the hydraulic components and nozzle of the marking system. This plugs up the inkjet printer. The quality of the marking suffers and the availability and reliability of the inkjet printer is reduced. Paul LEIBINGER confronted this problem and developed its own pigment ink printer in which the ink pigments cannot set.

- Special printer for pigmented inks (e.g. white, yellow, blue, orange)

- Non-contact marking of dark backgrounds

- High availability and reliability guaranteed

How does the JET 3UP PI do it? The combination of a unique hydraulic system with an integrated ink agitator and a fully automated interval mode for production shutdowns means that the ink regularly circulates through the entire inkjet printer. These processes prevent the pigments from permanently setting, for instance in white, yellow or orange pigmented ink.