Cassel

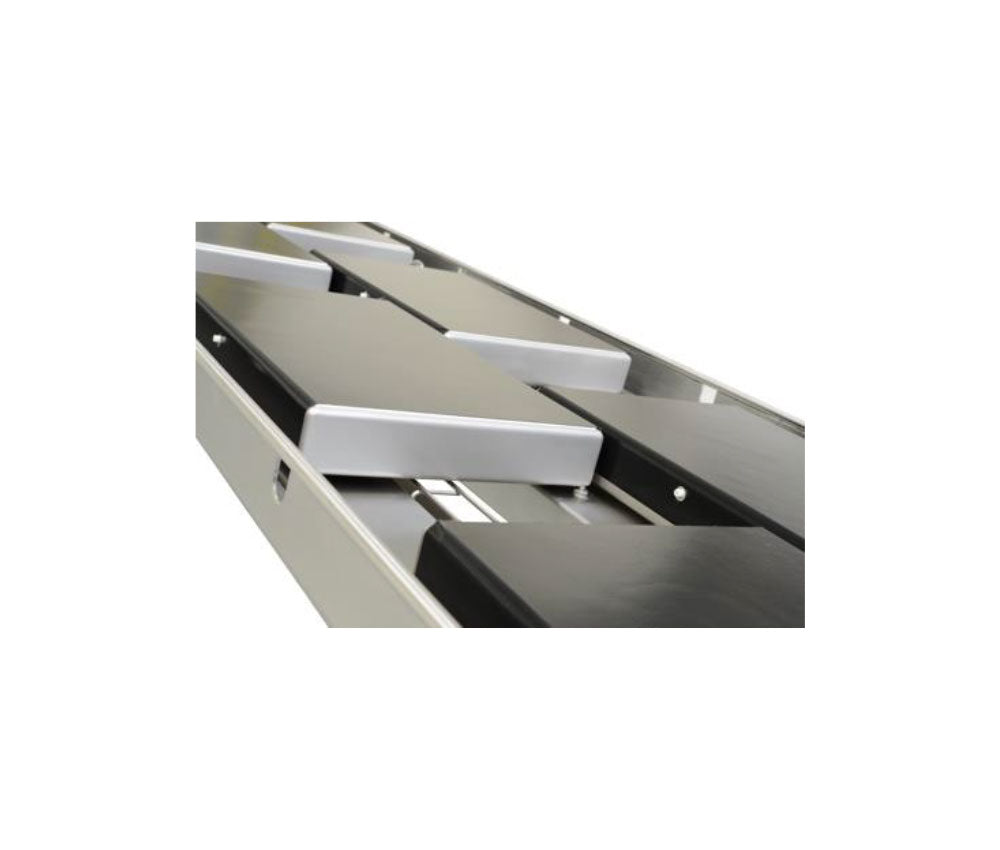

Metal Shark® Combi

Features

- Maximum search performance with highest reliability in the entire detection area due to 4-quadrant technology

- Simple setup with TeachAssistant

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password system, automatic log out after time lapse

- Sensitivity: Detects iron from 0.5 mm and stainless steel from 0.9 mm

Highlights

- Rotatable single sided sensor adapts perfectly to vertical or inclined product flow, available in widths up to 7 m / 23 ft.

- Overlapping multiple sensor heads allow for operators to identify contaminant position across the web width, potentially saving valuable material.

- Intuitive control and easy installation with autocalibration and Teach Assistant

- Automatic balance and calibration controls make the COMBI system essentially maintenance free.

- Documentation of all events and metal messages

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

- Cyclical function monitoring with Performance Validation System (PVS)

The detector’s design and dimensions will be customized to the production requirements.

Application

- Monitoring of flat products that are conveyed in webs or plates

- Quality assurance for incoming goods, outgoing goods or during running production

- Detection of broken needles and other metal parts in the textile industry

- Machine protection, e.g. in fleece or plate processing

Customization

The METAL SHARK® COMBI will be customized exactly to the production requirements

- freely selectable widths from 2 to 7 m and more

- freely selectable number of detection units

- individual support construction in adapted height, optionally available with vertically lowerable cross-beam or with lifting arms

Industries

- Paper

- Textile and fleece

- Wood processing (particle boards)