Cassel

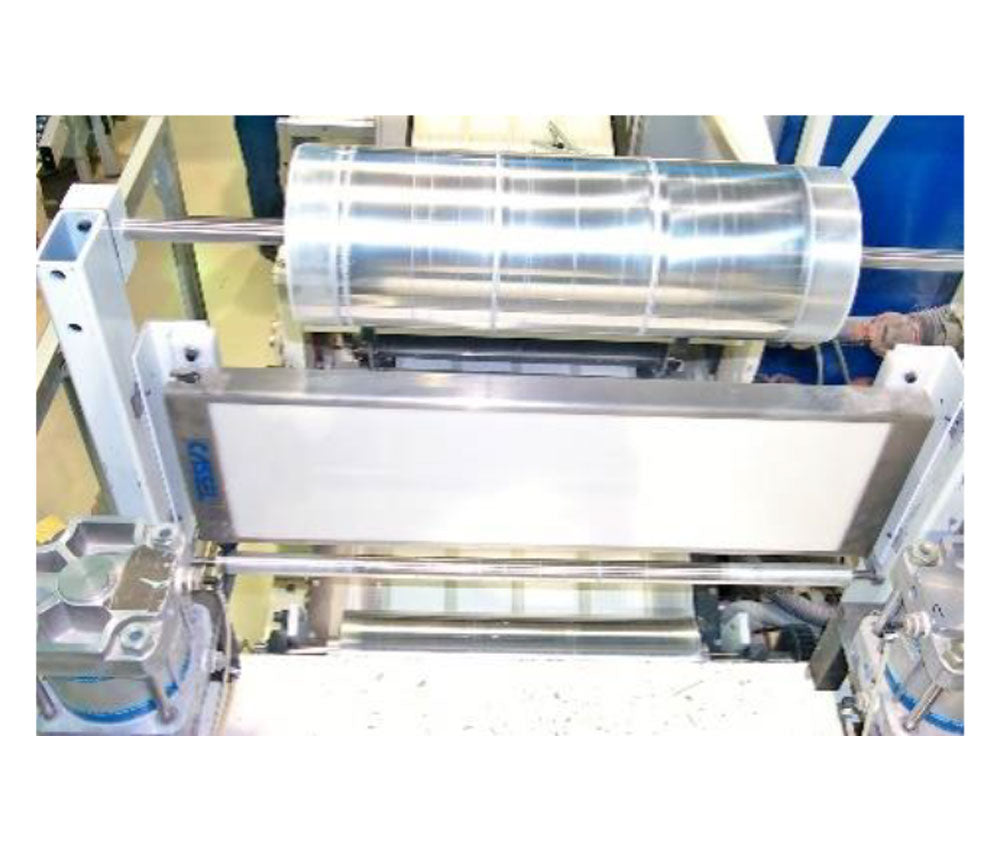

Metal Shark® FL

Key Features:

High Metal Detection Sensitivity

Detects ferrous, non-ferrous, and stainless steel metals with outstanding precision, even in difficult products such as conductive powders or highly product-loaded materials.

Free-Flow Inspection System

Designed for gravity conveyors, hoppers, chutes, and automated feeding lines.

Ideal for:

-

Raw materials

-

Powdered products

-

Dry ingredients

-

Granules & pellets

-

Food or chemical powders

SHARK® Ultra-Stable Technology

The intelligent analysis system automatically compensates for vibration, temperature fluctuations, and electrical interference, ensuring stable 24/7 detection performance.

Hygienic & Industrial Construction

-

Stainless steel frame

-

Designed for HACCP environments

-

Easy-to-clean surfaces

-

Resistant to dust and harsh conditions

Intuitive User Interface

Simple touchscreen display, multilingual menus, fast setup, and batch management.

Suitable for operators of all experience levels.