Bocedi

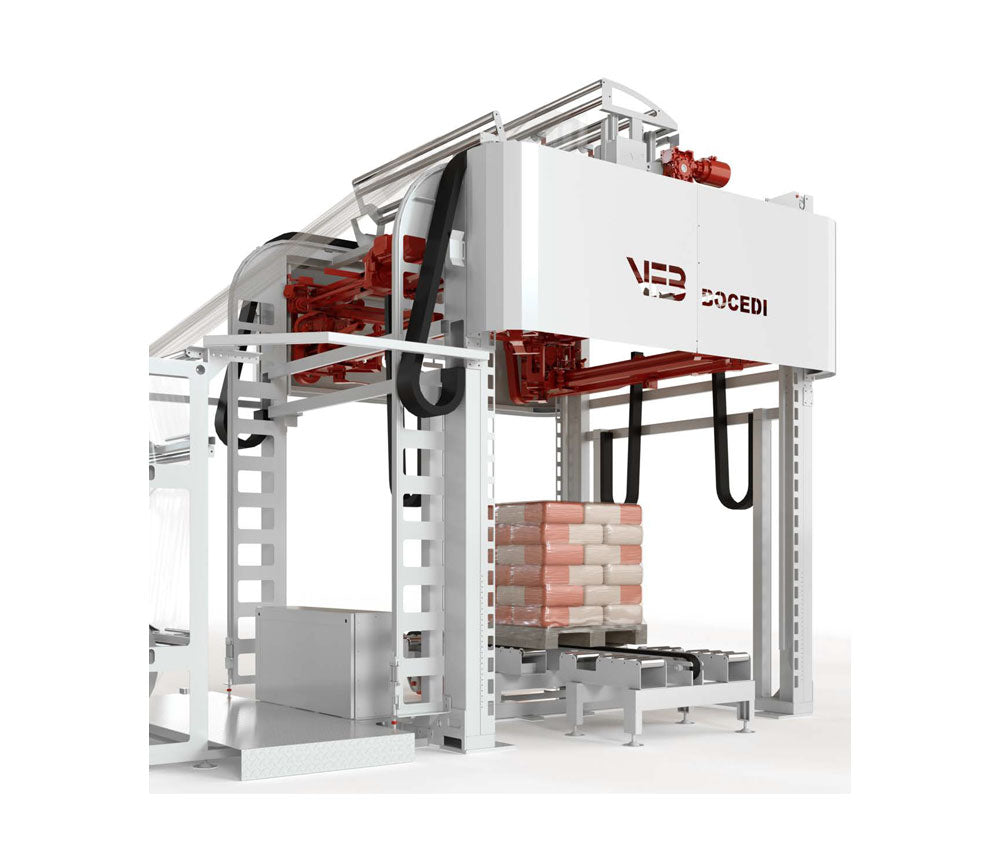

Stretch Hooder FB3000

The FB3000 works with optimised film thicknesses and reel dimensions to ensure minimum plastic usage. Stretch hood film is fully recyclable and can be produced

with recycled or bio based polymers. The overall process has a carbon neutral footprint, free from any gas emission.

- Excellent load stability

- Low downtimes

- Great branding & product display

- Water/weather-proof/UV protection

- Different pallet/load sizes on one machine

- Ideal for all goods, heat sensitive materials included

- Maintenance at operator level

- Smart HMI

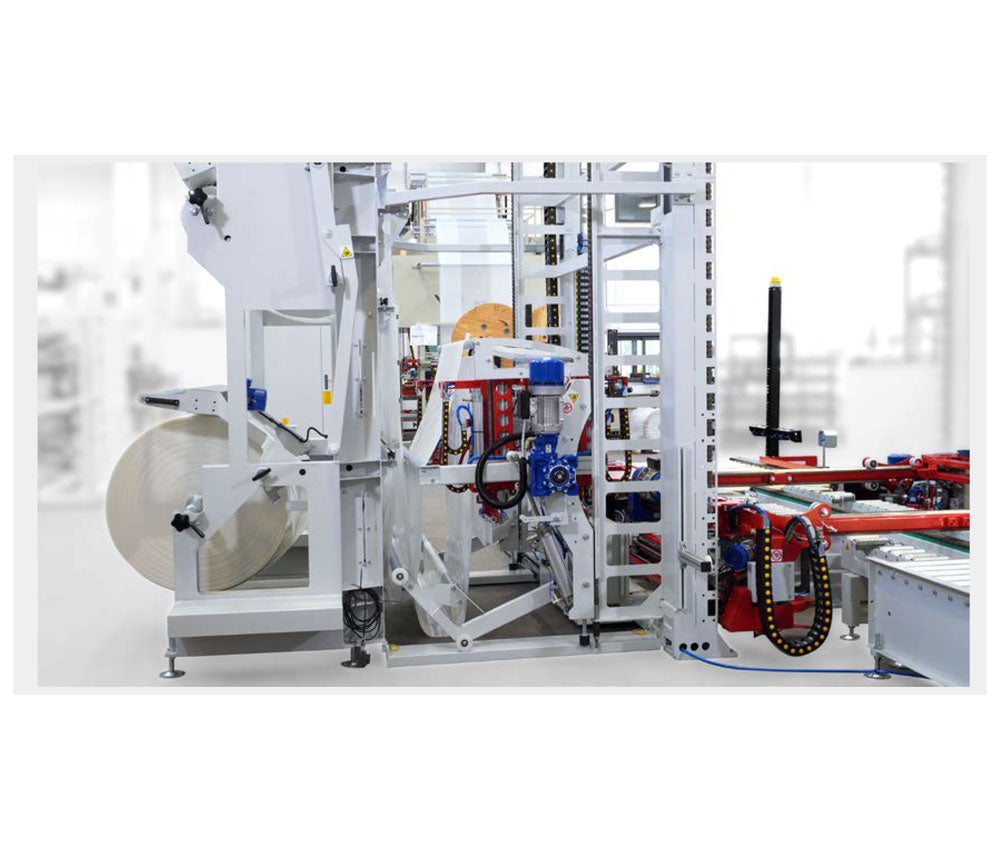

Automatic Load Identification System & Profile Control

The stretch hooder FB3000 is equipped with an automatic load identification system, designed to identify the height width and length of each load.

With the identified load dimensions, the FB3000 will automatically select which film size to use, from the configurated film reels, and will tailor cut the length of the hood for every single load, granting optimised film usage.

The hooder is also inclusive of a load profile control system, which automatically adjust the film position in relation to the load actual dimensions, keeping the perfect balance of films stretch forces.

Smart HMI

Simple easy to use with intuitive graphics, yet full of smart features. This is the new HMI developed to offer an up to date human machine interface, with the latest digital functionalities. All on Siemens MTP new generation touch display, with fast response time, also visible on portable devices.

Different access profiles, live diagnosis and selfcalibrating programs for new load sizes, are just some of the many features the new system can offer.

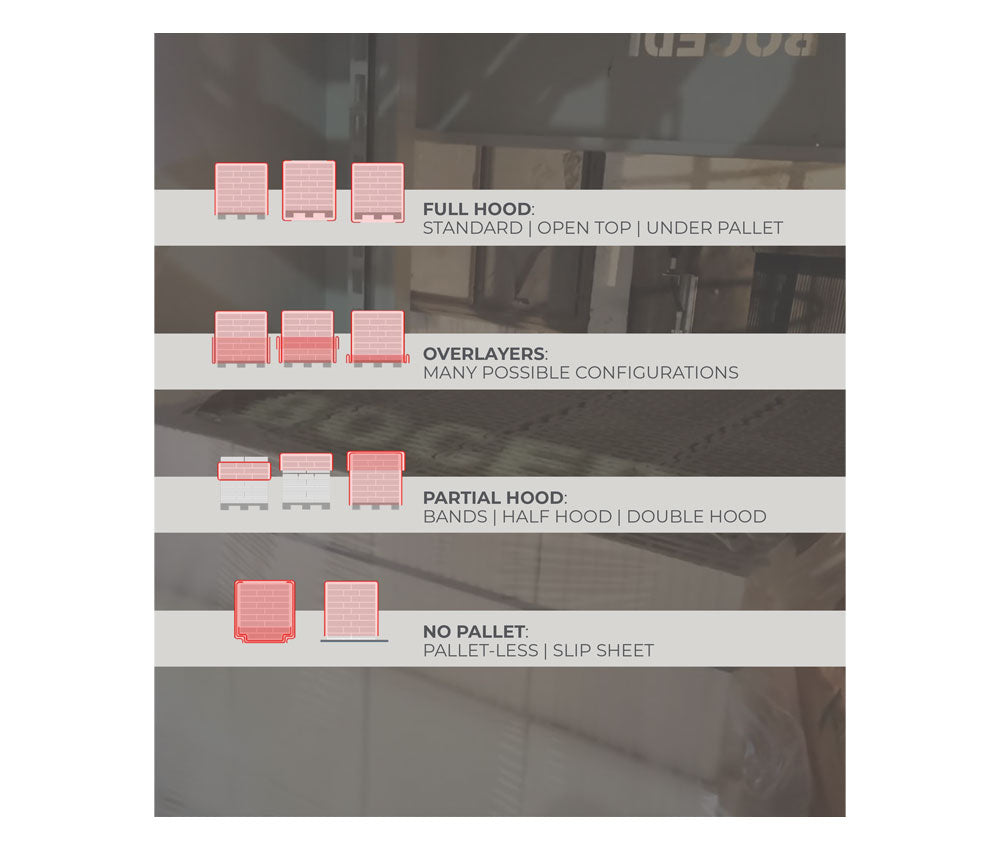

Flexible Packing

The FB3000 offers the possibility to apply different hood types on the single load. Combine whichever pallet finish matches your product , if it is a single full hood or a mix of different configuration the machine will automatically do the job.

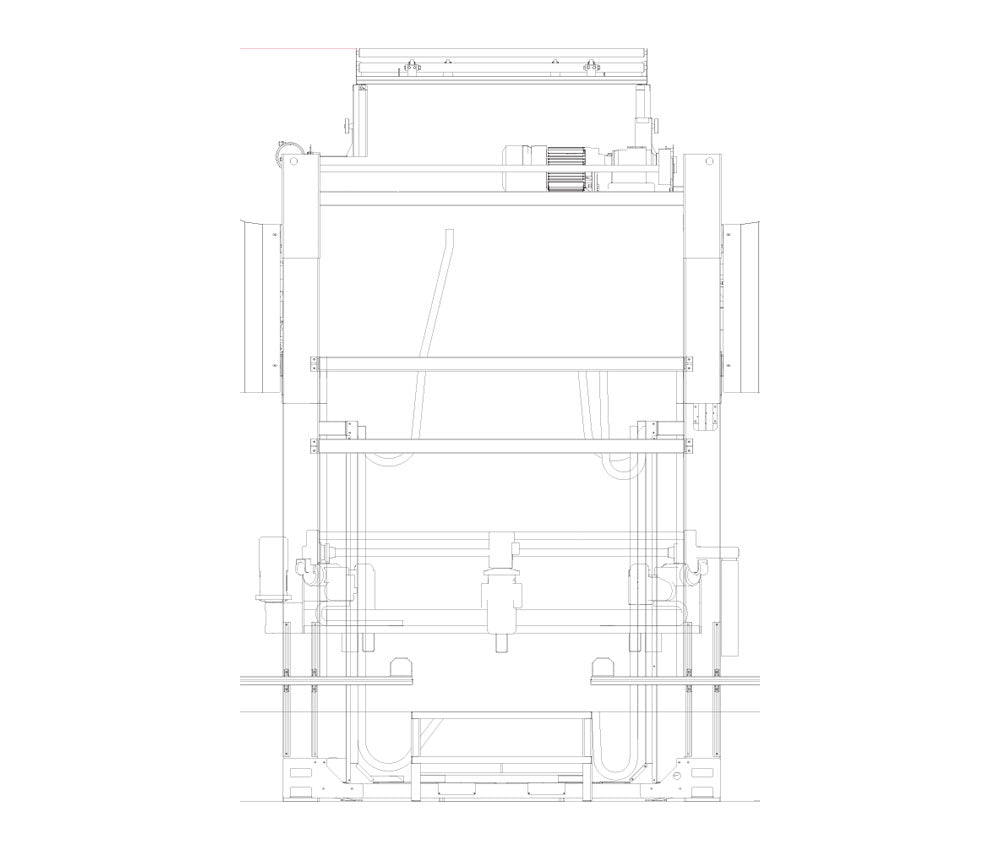

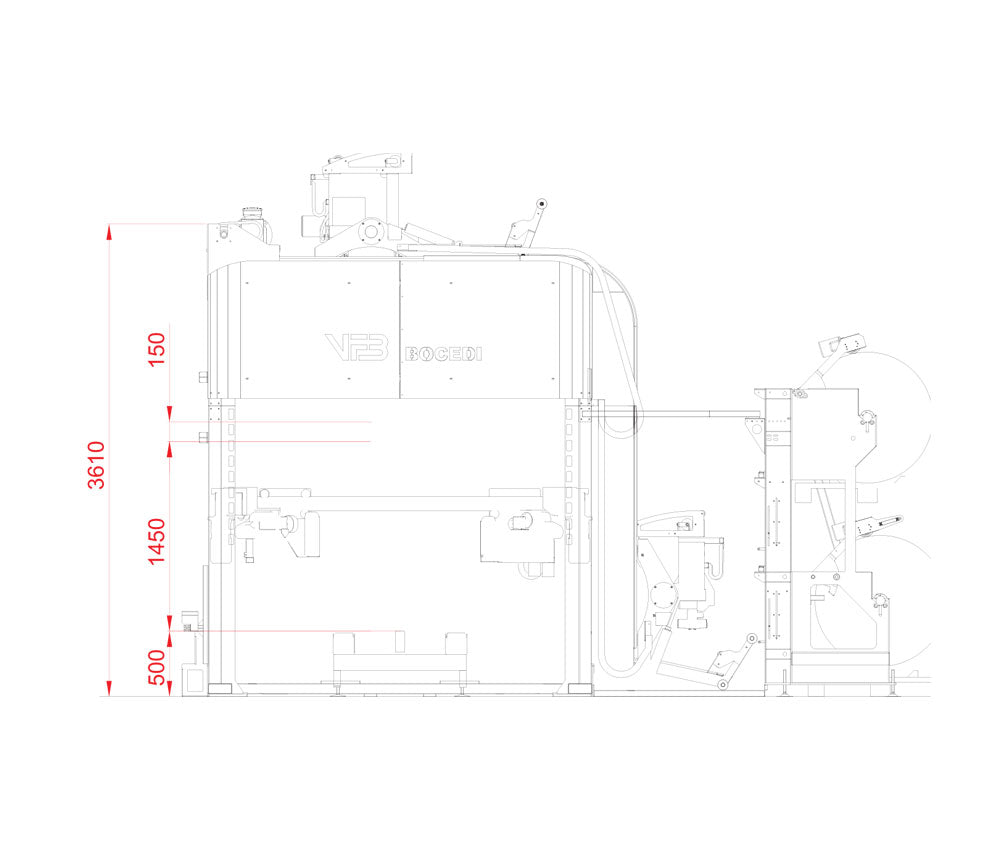

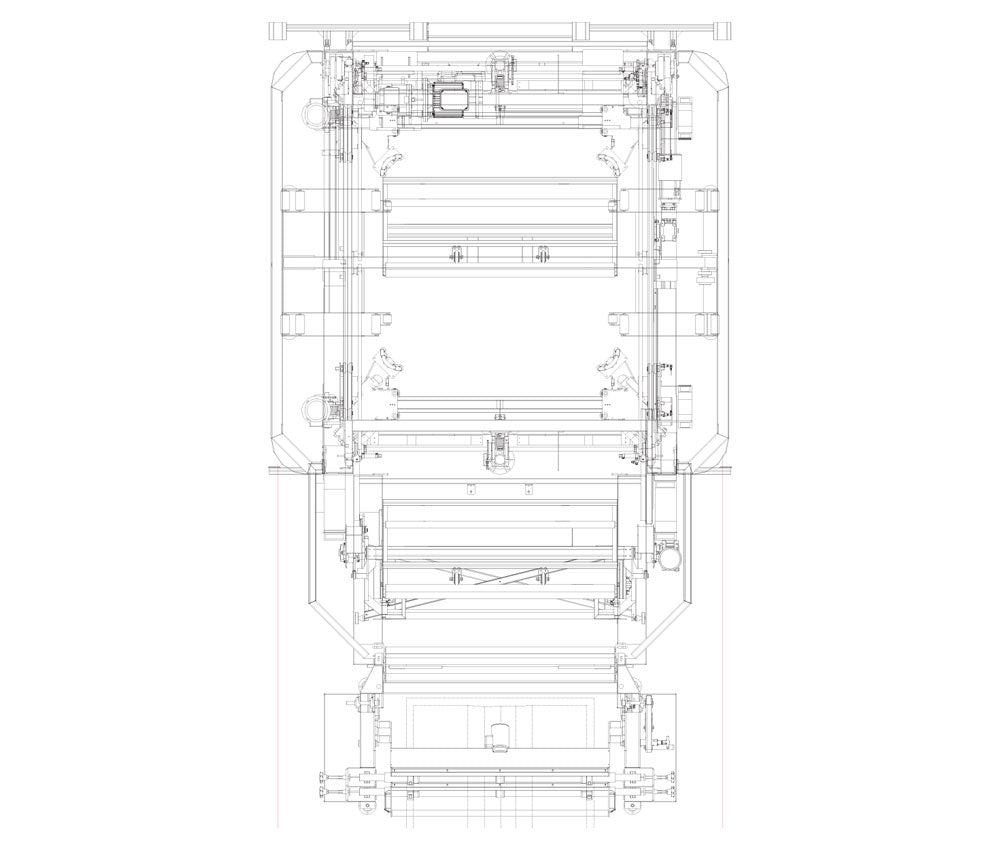

Layout

Based in the North of Italy , OFFICINA BOCEDI srl is the reliable equipment manufacturer for end of the line packaging systems. Its complete product range includes stretch and shrink hood machines, conveyance lines, vertical and horizontal strapping machines , in box bagmakers and a multitude of customisable accessories to fit the most demanding packaging cycle.

The company has skilfully diversified its production using the over 50 years of worldwide experience on the market to design and install dedicated solutions for specific sectors like bagged material, ceramics and building, food and beverage, paper and printing, domestic appliances, insulations and many others.

The customers’ needs and satisfaction are what lead the complete Bocedi team when designing the state-of-the-art packaging solutions, tailored machines and packaging cycles to offer a turnkey and perfect fit system. All the packaging machines are designed to secure the loads during shipping transits, to protect the loads against severe weather conditions by preserving the products’ original integrity.